The processes of designing and getting consumer electronics readied for the market tend to vary by the electronics’ specifications and the manufacturing process.

One of the most outstanding processes is the Electronics Manufacturing Service (EMS). It is usually a full-suite designing process for manufacturing consumer electronics. Today, it is commonly called the EMS PCB, as the Printed Circuit Board (PCB) is one of the common techniques used for designing and optimizing consumer electronics.

In this article, you will find out what the EMS PCB is all about.

What is EMS PCB?

It is a type of manufacturing process peculiar to consumer electronics. According to Wikipedia, it is a “term used for companies that design, manufacture, test, distribute, and provide return/repair services for electronic components and assemblies for Original Equipment Manufacturers (OEMs).”

It is therefore, on this basis, that we call the EMS PCB one of the core manufacturing processes used for providing a full-scale consumer electronics’ solution to the OEMs. By providing the EMS PCB service, the EMS PCB supplier is able to interface with the OEMs to offer the best consumer electronics’ optimizations for the end-users.

Understanding the Different Levels of EMS PCB Services

The type of EMS PCB service differs by the specifics. Although the EMS PCB supplier specializes in providing an all-around service, it is also possible that the company majors in one area. For example, you can find an EMS PCB company that only focuses on testing, designing and assembly the Printed Circuit Board (PCB). It is also possible for the company to offer component sourcing, PCB design, PCB assembly and testing.

It is therefore imperative to choose an EMS PCB supplier that either provides all these services or offers specific services that match your needs.

Can EMS PCB Services be Outsourced?

It may be possible for the EMS PCB services to be outsourced or made in the form of a collaboration between the EMS PCB company and another company. This typically happens when the EMS PCB company offers a few of the services or if it is not versed in specific services, such as PCB etching. In that case, the company can collaborate with another PCB manufacturer to get the job done.

Another aspect of the collaboration is between the EMS PCB service provider and the customers. In this case, the provider wants to customers to provide some of the items while it handles the rest.

It is common for the EMS PCB company to ask the customers to provide the components and the designs before carrying on with the design. The EMS PCB provider may also want to handle the component sourcing, PCB assembly and testing – but would require the customers to provide the design file.

In all of the above, you want to make sure that the EMS PCB company is clear about the type of service it offers and the extent it would go. You can then decide if you would be able to go along with the other requirements on your part or not.

The Types of EMS PCB Services

The type of service you are to get from the EMS PCB manufacturer depends on the company’s manufacturing process.

Generally, there are different types of Electronics Manufacturing Services (EMS) and each of those has unique benefits.

Below is a breakdown of the different types of EMS PCB services:

1. Component Sourcing

One of the major reasons why consumer electronics’ manufacturers work with EMS PCB companies is because of the hassles associated with sourcing for components.

For some customers, picking the right components could prove a herculean task, especially since they aren’t versed in that area.

Therefore, handing over the component or part sourcing to the EMS PCB company is a smart way to get the right components and in good time.

On its part, the EMS PCB company helps the customers to pick the best components and at affordable costs.

2. EMS PCB Design Services

Providing EMS PCB designs is the second-next service that the company provides. This involves the provision of a wide range of services designed to help the consumers make the most out of the Printed Circuit Board (PCB).

Usually, the EMS PCB design is processed after the company had confirmed its capability to handle the consumers’ expectations of the PCB.

At this point, the EMS PCB manufacturer performs certain actions, depending in its capabilities. Below are some of the common design processes used by the EMS PCB companies:

3. Product Outlining

This is usually the first process, and it involves the provision of a concept for the Printed Circuit Board (PCB).

The processes used here range from making a preliminary specification of the PCB, followed by the detailing of the major objectives of the PCB.

The EMS PCB company also specializes in the researching of the underling processes of the PCB, including the exploration of the existing related products or PCBs that may aid in the design of the PCB in view.

4. EMS PCB Manufacturing

The EMS PCB company also provides a wide range of Printed Circuit Board (PCB) manufacturing services. It is pertinent to mention here that the manufacturing process involves the production of different kinds of electronic products.

Generally, the Printed Circuit Board (PCB) design process is based on the overall performance of the PCB in terms of the target applications.

PCB Design Technology

The technologies or design processes used when manufacturing Printed Circuit Boards (PCBs) also differ. The preferred design process or technology is based on the type of consumer electronics to be manufactured.

For emphasis, there are two (2) major design processes used when manufacturing PCBs. These are the:

- Surface Mount Technology: also called the SMT, the Surface Mount Technology involves the soldering of the electronic components to the PCB’s surface. It is important to point out here that the SMT design process also facilitate the EMS PCB process because of the quickened pace of picking and positioning the components on the circuit board’s surface.

- Through-Hole Technology: also called the THT, the Through-Hole Technology process involves the insertion of leads through the holes made in the circuit board. From there, the leads would be soldered into place before the electronic components are mounted on the board.

Varieties of EMS PCB Design

The differences in the outcome of the EMS PCB design also depend on the type of board to be manufactured. For context, most PCBs are classified into the Rigid PCB, but there are also other variants like:

- Flexible PCBs

- Rigid-Flex PCBs

Wireless Consumer Electronics

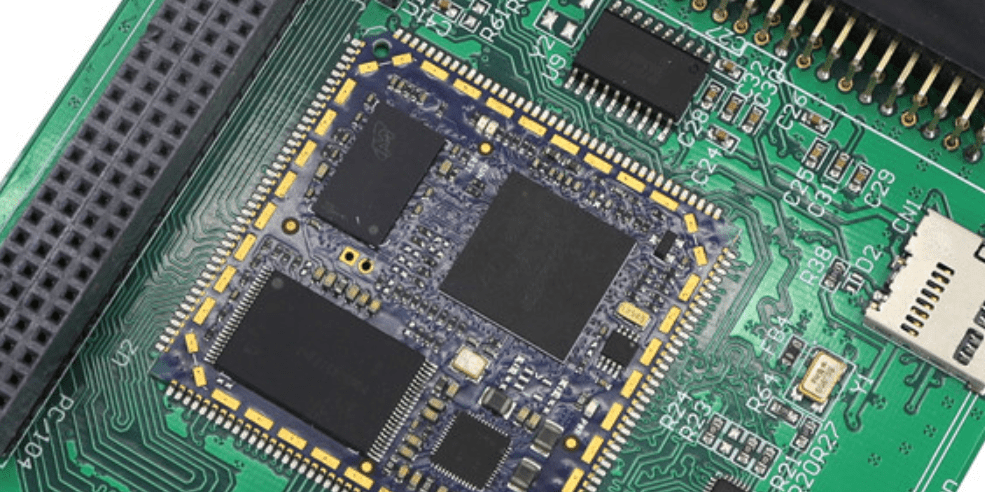

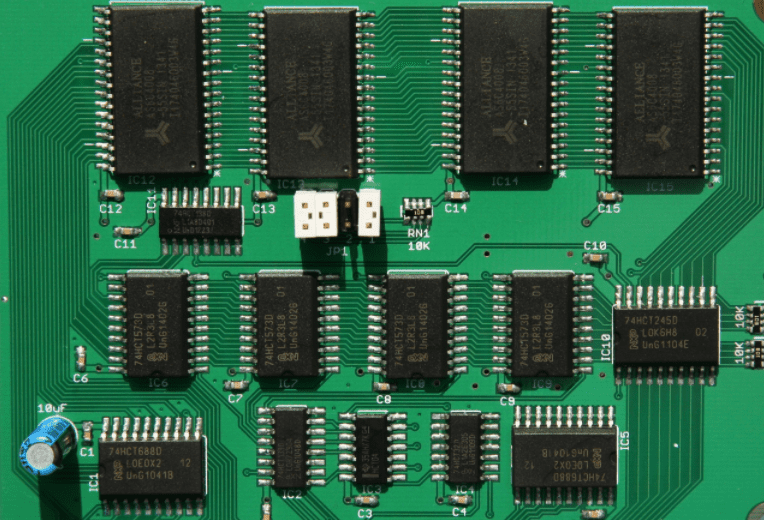

Printed Circuit Boards (PCBs) are “flat boards that hold electronic components.” However, they are one of the different electronic products made using the Electronics Manufacturing Service (EMS) as the basis.

The other type is the Radio Frequency (RF) and Wireless consumer electronics. This type of electronic product provides wireless communication and commonly comes in handy when working with data transfer and telecommunication applications.

If your preferred EMS PCB company provides this service, it is possible that the company can offer different variants. The variations cut across wireless devices and Radio Frequency Identification Devices (RFIDs).

Microelectronics Production

Aside from specializing in EMS PCB design, the company can also manufacture microelectronics, which are smaller semiconductor components.

Microelectronics’ production might not take all the time because of the lower volume and the less-strenuous design process.

The common types of microelectronics are:

- Chip-on-Board: also called the COB, the Chip-on-Board involves the bonding or attachment of bare dies to the Printed Circuit Board (PCB).

- Flip Chips: these are specific kinds of microelectronics designed as Integrated Circuits (ICs) that use solder bumps on the IC to connect to the external circuitry.

EMS PCB Testing

If the EMS PCB supplier handles the testing, you can be sure of getting a fully-functional circuit board. There are different kinds of EMS PCB testing procedures and the one you choose depends on the expected outcome.

Note that the EMS PCB testing can be done either before deploying the finished product/PCB or as soon as the EMS PCB prototype is completed.

Below are examples of some of the popular testing procedures for EMS PCB:

- X-Ray Testing: this is one of the most popular testing procedures for the EMS PCB. It makes an in-depth testing and analysis of the whole PCB.

- Agency Compliance: this type of testing is done to ensure that the EMS PCB complies with the quality and safety guidelines of the specific standards of the governing agency.

- Functional Testing: this type of testing is done to ascertain the overall performance of the EMS PCB’s internal components.

- Automated Optical Inspection: this is a type of EMS PCB testing used for identifying defects in the circuit board design. The inspection also covers the identification of improper holing (assuming the EMS PCB uses the Surface Mount Technology), excess soldering and fixing the broken traces.

EMS PCB Production

The design and production of the EMS PCB is different. While the former has to do with the conceptualization of the circuit board, the latter has to do with the overall delivery of the desired circuit board.

There are different aspects to the EMS PCB production and a few of those have been covered below:

Specialized Production

As the name suggests, this is a special kind of EMS PCB production. Some EMS PCB suppliers don’t engage in this and often collaborate with other companies to offer this kind of service.

Examples of the specialized EMS PCB services include:

- PCB etching

- Cabling services

- Quick-turn production

They are called specialized services because of the extra efforts and the time it would take to get the job done. Make sure that your preferred EMS PCB company can handle this – or can at least, partner with another company that can.

EMS PCB Prototyping

This is more like a “demo version” of the final design of the Printed Circuit Board (PCB). It typically follows the design phase and is geared towards helping the consumers get “early samples” of the PCB to decide on whether changes need to be made or not.

The Volume of the EMS PCB

How many EMS PCBs are you looking to order? There are two (2) major volumes – the low and the high. While the former has to do with a limited number of EMS PCBs, the latter deals with larger volumes or higher quantities of the circuit boards.

Note, however, that the categorization can also extend to High Mix Low Volume (HMLV), High Volume Low Mix (HVLM) and Medium Volume.

Note that the volumes are relative, in the sense that the production capabilities of the EMS PCB manufacturer are always considered. Generally, low volume EMS PCBs should be below 100; the medium volume should not exceed 10,000 EMS PCBs, while the high-volume EMS PCBs can be above 10,000 units.

Who is the Best EMS PCB Manufacturer?

The choice of a reliable EMS PCB supplier or manufacturer should be based on different factors. If you are looking for a reliable manufacturer to produce your EMS PCBs, reach out to RayPCB. We specialize in full-suite EMS PCB production, meaning that we take the hassle off you so we can handle every aspect of the job from start to finish.

With that being said, here are some of the factors you want to consider before choosing an EMS PCB manufacturer:

What is the EMS PCB Supplier’s Design Process?

You have to find out the processes involved in designing the EMS PCB? The EMS PCB manufacturer should also have the relevant technologies and modern equipment that would aid the design process.

Years of Experience

How long has the EMS PCB manufacturer being in the business? The extensive history and expertise in the industry helps the consumers to have the confidence to work with a company that has over the last couple of years, proved to be an expert in the industry.

Final Words: Choosing between EMS PCB and OEM

The choice of choosing between an EMS PCB provider/manufacturer and an Original Equipment Manufacturer (OEM) differs by some factors. While the EMS PCB supplier helps to create the PCB products and offer related value-added services for the OEM, the OEM, on the other hand, markets the products.

You should also consider choosing the EMS PCB supplier over the OEM because the former provides extensive services ranging from design, repair and supply chain management, while the OEM does more of designing the Printed Circuit Board (PCB).

Comments are closed