A four-layer circuit board is a type of printed circuit board (PCB) that has four layers of conductive material separated by layers of non-conductive material. It is commonly used in electronic devices that require a high level of complexity and precision, such as computers, smartphones, and medical equipment. The four-layer design allows for more components to be placed on the board, which increases functionality and reduces the size of the device.

The first layer of a four-layer circuit board is typically the signal layer, which contains the traces that carry electrical signals from one component to another. The second and third layers are the power and ground planes, respectively, which provide a stable voltage and ground reference for the components on the board. The fourth layer is the bottom signal layer, which is similar to the top signal layer and contains additional traces that connect to the components on the board.

Overall, a four-layer circuit board offers many advantages over simpler designs, including increased functionality, reduced size, and improved reliability. As technology continues to advance, it is likely that four-layer boards will become even more common in electronic devices of all kinds.

What is a 4 Layer Circuit Board?

A 4 layer circuit board is a type of printed circuit board (PCB) that has four layers of conductive material separated by insulating layers. It is commonly used in electronic devices that require more complex circuitry than can be accommodated on a single or double-layer PCB.

The four layers of a 4 layer circuit board are typically arranged in the following order: signal layer, ground plane, power plane, and signal layer. The signal layers are used for routing signals between components, while the ground and power planes provide a stable reference voltage for the circuit and help to reduce noise and interference.

One of the main advantages of using a 4 layer circuit board is that it allows for a higher density of components to be placed on the board, which can help to reduce the size of the overall device. Additionally, the use of ground and power planes can help to improve the performance and reliability of the circuit.

Overall, 4 layer circuit boards are a popular choice for many electronic devices due to their ability to accommodate complex circuitry in a compact and reliable package.

Benefits of 4 Layer Circuit Boards

Improved Signal Integrity

One of the primary benefits of 4 layer circuit boards is improved signal integrity. With more layers, designers can create more complex and compact circuits, which results in less signal noise and better signal quality. This is particularly important for high-speed digital circuits where signal integrity is critical.

Increased Design Flexibility

Another benefit of 4 layer circuit boards is increased design flexibility. With more layers, designers have more space to work with, which allows them to add more components and create more complex circuits. This can be especially useful for devices that require a lot of processing power or that have multiple functions.

Reduced Electromagnetic Interference

A third benefit of 4 layer circuit boards is reduced electromagnetic interference. With more layers, designers can create circuits with better shielding, which helps to reduce the amount of electromagnetic interference that can affect the performance of the device. This is particularly important for devices that operate in noisy environments or that need to be highly reliable.

In summary, 4 layer circuit boards offer a number of benefits over simpler circuit board designs. They provide improved signal integrity, increased design flexibility, and reduced electromagnetic interference. These benefits make them an excellent choice for a wide range of electronic devices.

Design Considerations for 4 Layer Circuit Boards

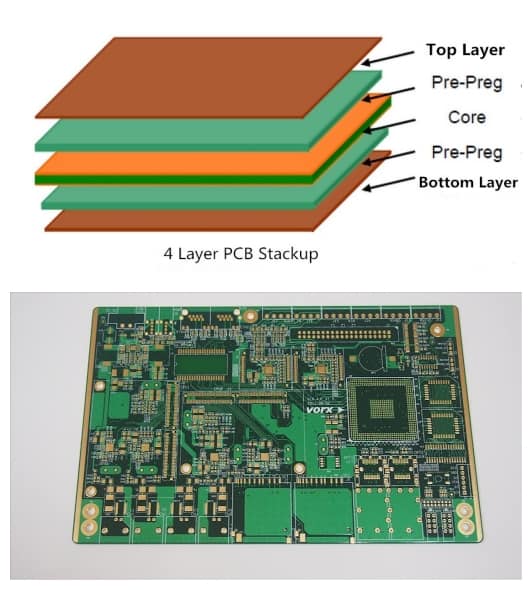

Layer Stackup

The layer stackup is an important consideration when designing a 4 layer circuit board. It determines the order and placement of the layers, which can affect the board’s performance. The most common layer stackup for a 4 layer circuit board is signal-ground-power-signal. This stackup provides a good balance between signal integrity and power distribution.

Trace Width and Spacing

Trace width and spacing are critical factors in the design of a 4 layer circuit board. The width of the trace determines the amount of current that can flow through it, while the spacing between the traces determines the level of isolation between them. It is important to ensure that the trace width and spacing are appropriate for the current and voltage levels in the circuit.

Via Placement

Via placement is another important consideration when designing a 4 layer circuit board. Vias are used to connect the various layers of the board and provide a path for current to flow. It is important to ensure that the vias are placed in a way that minimizes signal interference and maximizes the board’s performance.

Ground Planes

Ground planes are an essential part of a 4 layer circuit board. They provide a low-impedance path for current to flow and help to reduce electromagnetic interference. It is important to ensure that the ground planes are properly connected and that they are placed in a way that minimizes signal interference.

In summary, when designing a 4 layer circuit board, it is important to consider the layer stackup, trace width and spacing, via placement, and ground planes. These factors can have a significant impact on the board’s performance and should be carefully considered during the design process.

Manufacturing Process for 4 Layer Circuit Boards

Drilling

The first step in manufacturing a 4 layer circuit board is drilling. This process involves drilling holes through the board where components will be placed. These holes are typically drilled using a computer-controlled drilling machine, which ensures precision and accuracy.

Copper Plating

After the drilling process, the board is then plated with copper. This process involves adding a thin layer of copper to the surface of the board, which helps to conduct electricity. The copper is plated onto the board using an electroplating process, which involves immersing the board in a solution of copper ions and applying an electric current.

Lamination

Once the copper plating process is complete, the board is then laminated. This involves layering the board with a thin sheet of insulating material, such as fiberglass. The layers are then pressed together using heat and pressure to create a solid, multi-layered board.

Etching

The final step in the manufacturing process is etching. This involves removing the excess copper from the board using a chemical process. The areas where components will be placed are protected with a layer of resist, which prevents the copper from being etched away. The board is then washed and dried to remove any remaining chemicals.

Overall, the manufacturing process for 4 layer circuit boards is a complex and precise process that requires specialized equipment and expertise. By following these steps, manufacturers can create high-quality circuit boards that are reliable and efficient.

Applications of 4 Layer Circuit Boards

Consumer Electronics

4 layer circuit boards are commonly used in consumer electronics such as smartphones, tablets, laptops, and gaming consoles. These devices require high-speed data transfer rates, which can be achieved through the use of multiple layers. Additionally, 4 layer circuit boards can help reduce the size of these devices, making them more compact and lightweight.

Telecommunications

Telecommunications equipment such as routers, switches, and modems also benefit from the use of 4 layer circuit boards. These devices require high-frequency signals and low noise levels, which can be achieved through the use of multiple layers. Additionally, 4 layer circuit boards can help improve the reliability and durability of these devices, making them more resistant to environmental factors such as temperature and humidity.

Medical Devices

Medical devices such as pacemakers, insulin pumps, and hearing aids also use 4 layer circuit boards. These devices require high levels of precision and accuracy, which can be achieved through the use of multiple layers. Additionally, 4 layer circuit boards can help improve the safety and reliability of these devices, making them more effective at treating various medical conditions.

In conclusion, 4 layer circuit boards have a wide range of applications in various industries, including consumer electronics, telecommunications, and medical devices. These circuit boards provide high-speed data transfer rates, low noise levels, and high levels of precision and accuracy, making them an essential component in many devices today.

Comments are closed