HDIs (High Density Interconnects) PCBs are the backbone of modern electronic devices, providing the necessary connectivity and functionality. They are the go-to solution for applications that require complex circuitry in a small form factor. As a result, the demand for HDI PCBs has increased significantly over the years, and so has the number of suppliers offering them.

Choosing the right HDI PCB supplier is crucial to ensure the quality, reliability, and performance of the final product. A reliable supplier should have a proven track record of delivering high-quality HDI PCBs that meet the customer’s specifications and requirements. They should also have the necessary expertise, technology, and resources to design, manufacture, and test HDI PCBs in a timely and cost-effective manner. In addition, they should be able to provide excellent customer service and technical support throughout the entire process, from design to delivery.

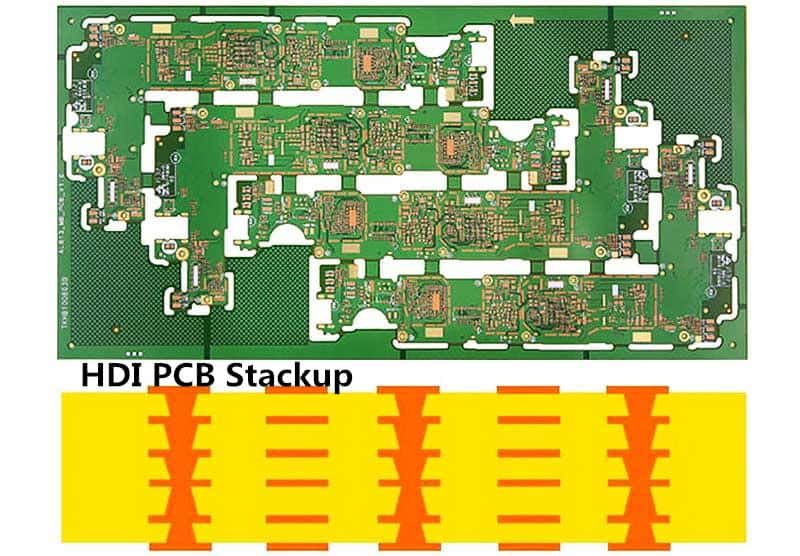

What is HDI PCB?

High Density Interconnect (HDI) PCB is a type of printed circuit board that is designed to have a higher wiring density than traditional PCBs. HDI PCBs are used in a wide range of applications, including smartphones, tablets, and other portable electronic devices. They are also used in high-performance computing systems, aerospace, and medical devices.

HDI PCBs are made using advanced manufacturing techniques that allow for more complex and compact designs. They typically have several layers of copper interconnects and vias, which are small holes that allow for the connection of different layers of the PCB. This allows for a higher density of components to be placed on the board, resulting in smaller and more compact designs.

There are several types of HDI PCBs, including microvia, stacked via, and build-up PCBs. Microvia PCBs use small diameter holes to connect different layers of the PCB, while stacked via PCBs use stacked vias to connect multiple layers. Build-up PCBs use multiple layers of thin copper sheets that are laminated together to create a more complex design.

Overall, HDI PCBs are an important technology for the development of compact and high-performance electronic devices. They offer a wide range of benefits, including increased design flexibility, improved signal integrity, and reduced size and weight.

Why Choose an HDI PCB Supplier?

When it comes to printed circuit boards (PCBs), high-density interconnect (HDI) technology is becoming increasingly popular. This technology allows for more connections in a smaller space, making it ideal for compact devices such as smartphones, wearables, and other consumer electronics. Choosing an HDI PCB supplier can offer several benefits, including:

Benefits of using an HDI PCB supplier

- Compact design: HDI technology allows for more connections in a smaller space, making it possible to design smaller and more compact devices.

- Improved performance: With more connections, HDI PCBs can handle higher frequencies and faster data transfer rates, resulting in improved device performance.

- Cost savings: HDI PCBs may require fewer layers and components, resulting in lower material and assembly costs.

- Enhanced reliability: HDI PCBs have fewer vias, which can reduce the risk of failure due to thermal stress or vibration.

- Customization: HDI PCBs can be customized to meet specific design requirements, including impedance control, signal integrity, and power distribution.

Factors to consider when choosing an HDI PCB supplier

When choosing an HDI PCB supplier, there are several factors to consider, including:

- Experience and expertise: Look for a supplier with experience in HDI technology and a proven track record of producing high-quality HDI PCBs.

- Manufacturing capabilities: Ensure that the supplier has the necessary equipment and capabilities to produce HDI PCBs that meet your design requirements.

- Quality control: Look for a supplier that has a robust quality control process to ensure that each PCB meets your specifications and is free from defects.

- Cost-effectiveness: Compare prices from different suppliers to ensure that you are getting a competitive price for your HDI PCBs.

- Lead time: Consider the lead time required for production and delivery of your HDI PCBs to ensure that they will be delivered on time.

In conclusion, choosing an HDI PCB supplier can offer several benefits, including improved performance, cost savings, and enhanced reliability. When selecting a supplier, consider their experience, manufacturing capabilities, quality control, cost-effectiveness, and lead time to ensure that you receive high-quality HDI PCBs that meet your design requirements.

Top HDI PCB Suppliers

When it comes to HDI PCBs, there are a few suppliers that stand out in the market. Here are three of the top suppliers you might consider:

Supplier 1

Supplier 1 is a leading manufacturer of HDI PCBs. They offer a wide range of products that are suitable for various applications, including smartphones, laptops, and other electronic devices. They use advanced technology and modern equipment to produce high-quality PCBs that meet the industry standards. Supplier 1 has a team of experienced engineers who work closely with their clients to ensure their needs are met. They also provide excellent customer support and fast delivery times.

Supplier 2

Supplier 2 is another reliable supplier of HDI PCBs. They have been in the business for many years and have a proven track record of producing high-quality products. They use state-of-the-art technology and equipment to manufacture their PCBs, ensuring that they are of the highest quality. Supplier 2 has a team of skilled engineers who are dedicated to providing their clients with the best possible service. They offer a wide range of products that are suitable for various applications, including medical devices, automotive electronics, and aerospace applications.

Supplier 3

Supplier 3 is a leading supplier of HDI PCBs. They have a wide range of products that are suitable for various applications, including smartphones, tablets, and other electronic devices. They use advanced technology and modern equipment to produce high-quality PCBs that meet the industry standards. Supplier 3 has a team of experienced engineers who work closely with their clients to ensure their needs are met. They also provide excellent customer support and fast delivery times.

In conclusion, when it comes to HDI PCB suppliers, these three companies are among the best in the market. With their advanced technology, experienced engineers, and excellent customer support, they are sure to provide you with the best possible service.

How to Evaluate an HDI PCB Supplier

When it comes to evaluating an HDI PCB supplier, there are several factors that you should consider in order to ensure that you are getting the best quality PCBs for your needs. The following sub-sections outline some of the key factors to consider when evaluating an HDI PCB supplier.

Quality Standards

One of the most important factors to consider when evaluating an HDI PCB supplier is their quality standards. You should look for a supplier that has a proven track record of producing high-quality PCBs that meet or exceed industry standards. Some of the key quality standards to look for include:

- ISO 9001:2015 certification

- UL certification

- RoHS compliance

In addition to these certifications, you should also look for a supplier that has a rigorous quality control process in place to ensure that each PCB meets your specifications and requirements.

Delivery Times

Another important factor to consider when evaluating an HDI PCB supplier is their delivery times. You should look for a supplier that can deliver high-quality PCBs within a reasonable timeframe that meets your project deadlines. Some of the key factors that can impact delivery times include:

- Order volume

- Manufacturing capacity

- Shipping times

You should also look for a supplier that has a reliable shipping process in place to ensure that your PCBs arrive on time and in good condition.

Pricing

Finally, pricing is also an important factor to consider when evaluating an HDI PCB supplier. You should look for a supplier that offers competitive pricing without sacrificing quality or delivery times. Some of the key factors that can impact pricing include:

- PCB size and complexity

- Order volume

- Material costs

You should also look for a supplier that offers transparent pricing and is willing to work with you to find a solution that meets your budget and quality requirements.

In conclusion, when evaluating an HDI PCB supplier, it’s important to consider their quality standards, delivery times, and pricing to ensure that you are getting the best value for your investment.

Conclusion

In conclusion, selecting the right HDI PCB supplier is crucial for the success of any project. With the increasing demand for smaller and more complex PCBs, finding a reliable supplier who can provide high-quality HDI PCBs is essential.

When choosing a supplier, it is important to consider factors such as experience, quality control measures, and customer service. A supplier with a proven track record of delivering high-quality HDI PCBs and a commitment to quality control is more likely to meet your project requirements.

Additionally, a supplier with excellent customer service can help ensure that your project runs smoothly and any issues are promptly addressed. This can save time and money in the long run.

Overall, investing time in finding the right HDI PCB supplier can pay off in the form of a successful project. With the right supplier, you can rest assured that your HDI PCBs will meet your specifications and be delivered on time.

Comments are closed