Does the color of a Printed Circuit Board (PCB) matter of have a role to play in the overall functions? It appears the general submission is “no,” but there could be a couple of relevance the solder mask makes.

It is common to have PCBs with green solder masks, and in recent times, we have seen the white PCBs and pink circuit board solder masks. In this article, we will review the Purple PCB, one of the many circuit boards with a different solder mask, other than green.

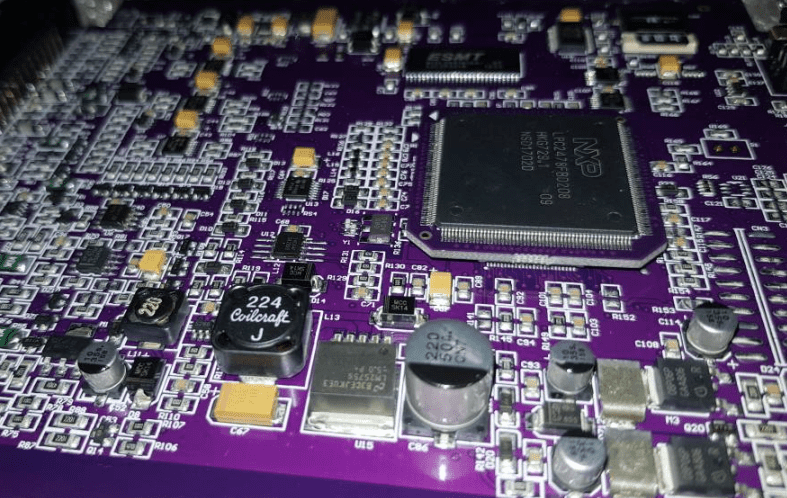

What is a Purple PCB?

To put it simply, a Purple PCB is a circuit board with a purple solder mask. The solder mask is the primary foundation for the color of a Printed Circuit Board (PCB). It is designed in the form of a lacquer with specific colors infused or added into it. These colors are used to hide the traces of bare copper on the circuit board.

Yet, the function of the solder mask is not limited to hiding the copper traces. The function also covers the protection of the circuit board’s copper foil from the oxidation processes and pollutants that tend to affect the overall performance of the circuit board.

To that end, you can deduce that the Purple PCB uses a purple solder mask or color to hide the copper traces while increasing the circuit board’s immunity against pollutants and oxidation.

In the subsequent paragraphs, you will find out if the color of the circuit board has any role or extra influence on the functions.

Benefits of Choosing the Purple PCB

If you are not particular about the solder mask color for your circuit board, then choosing the standard solder mask color of green would have been better.

But since most PCBs now come with preferences, you may have opted to go for the Purple PCB. If that be the case, the following are some of the reasons why it is a good decision:

Leakage Reduction

The Purple PCB has been credited with reducing leakages attributed to high impedances of the circuit board.

Circuit Board Functionality Tests

It is also possible to use the solder mask color of the PCB to determine the overall performance. This is tenable because of the subjection of the Purple PCB to series of tests to confirm the overall performance.

Purple PCB vs. Other Circuit Boards

One of the major comparisons or closest competitors to the Purple PCB is the Heavy Copper PCB. Here are some of the core differences between the two:

1. Thermal Distribution

The purple circuit board might not boast of the largest thermal distribution of heat dissipation capabilities than the heavy copper PCBs do. To that end, you want to be sure that the circuit board doesn’t assimilate more heat than it dissipates.

2. Performance and Ideal Applications

When it comes to how the Purple PCB is to be used, the use cases or applications are lower than those of the heavy copper circuit boards.

The reason for this is not far-fetched from the fact that the heavy copper PCBs are designed for use with the high-end and heavier applications. Considering that the Purple PCB is more of a standard PCB, the capabilities are limited.

3. Weight/Thickness

The weight or the thickness of a circuit board has to do with how heavy it can be. Depending on the application or where it is to be used, the weight can help bolster the durability of the circuit board.

The Purple PCB doesn’t weigh much, and that is because of the composition of less than 2mm. This is lower when compared to the thickness of the heavy copper PCB, which goes as high as 20 oz of copper per ft2.

Purple PCB Materials: The Best Options in the Market

The materials used in making a Printed Circuit Board (PCB) are as important as the performance of the circuit board at the end of the manufacturing process. Thus, choosing the best materials for your Purple PCB is important.

If you are unsure of the material to go for, don’t worry, as we have made a list. Here is a detailed list of some of the best materials for the purple circuit board:

Polyester Resins

Do you want your purple circuit board to be flexible, i.e., usable with a broad range of applications? If so, go for the polyester resins, which are also called the Polyethylene Terephthalate (PET).

These materials are attributed to PCB’s flexibility, while offering higher moisture resistance and excellent electrical properties for the circuit boards.

FR4

This is one of the most popular purple PCB materials. The FR4 material comes in handy when fabricating the purple circuit board.

It can also be used for other purposes, such as improving the purple PCB’s signal integrity, making the board water-resistant and improving the circuit board’s insulation.

Epoxy Resins

These are purple PCB materials specifically used for improving the mechanical protective capabilities of the board.

Polyimide Resins

The polyimide resins are to be used for improving the physical resistance of the purple circuit board to both chemical exposure and excessive heat/thermal energy.

The other purple PCB materials include:

- Special boards, such as metal circuit boards and ceramic PCBs.

- Paper boards, such as FR-1, FR-2, and FR-3 circuit boards and;

- Composite boards, such as CEM-1 and CEM-2

- High Density Interconnect Printed Circuit Boards (HDI PCBs)

How to Manufacture the Purple PCBs

The major process technology for making purple circuit boards is through plaiting. For that purpose, there are four (4) dedicated plaiting methods, viz:

- Brushing Plaiting: this has to do with the plaiting of a limited area or space in the purple PCB.

- Through-Hole Plaiting: this plaiting method deals with the drilling of the purple Printed Circuit Board (PCB).

- Finger Plaited Plaiting: this involves the plaiting of rare metals, such as gold on both the board edge joints and the board edge of the connector. That way, it helps the purple PCB to have lower contact resistance and an improved abrasive resistance.

- Real Linkage Selective Method: this purple PCB plaiting method has to do with enabling the pinning capability of the circuit, especially to enable the pinning to Integrated Circuits (ICs), connectors and transistors.

Final Words

In conclusion, the purple Printed Circuit Board (PCB) is capable of having a higher general workability, but you want to watch out for potential downsides, such as paying premium for the optimization, as well as the lesser heat dissipation capabilities.

Comments are closed