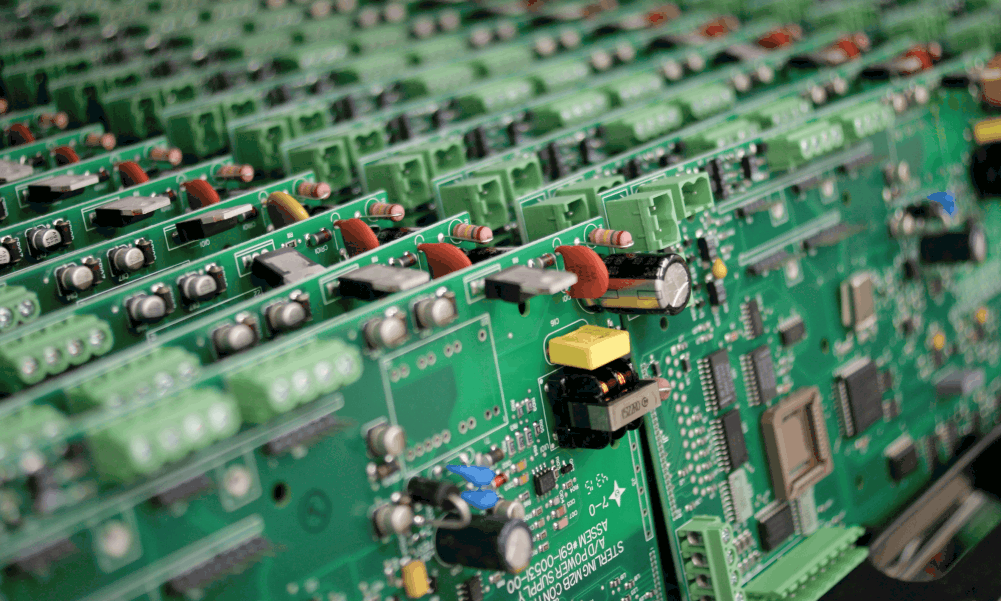

The popularity of Printed Circuit Boards (PCBs) is because they help to organize the structure of the electrical components used in any electronic product.

Besides, it is important to have an idea of how the entire system works. You want to know all there is to the PCB Assembly House. In this article, we will explain that and many other important factors in detail.

What Is PCB Assembly House?

PCB Assembly House can be viewed from different perspectives. The way you view it depends on what you think it is all about. That is why we evaluated the major perspectives to the PCB Assembly House so you can have a definite place to pitch your tent.

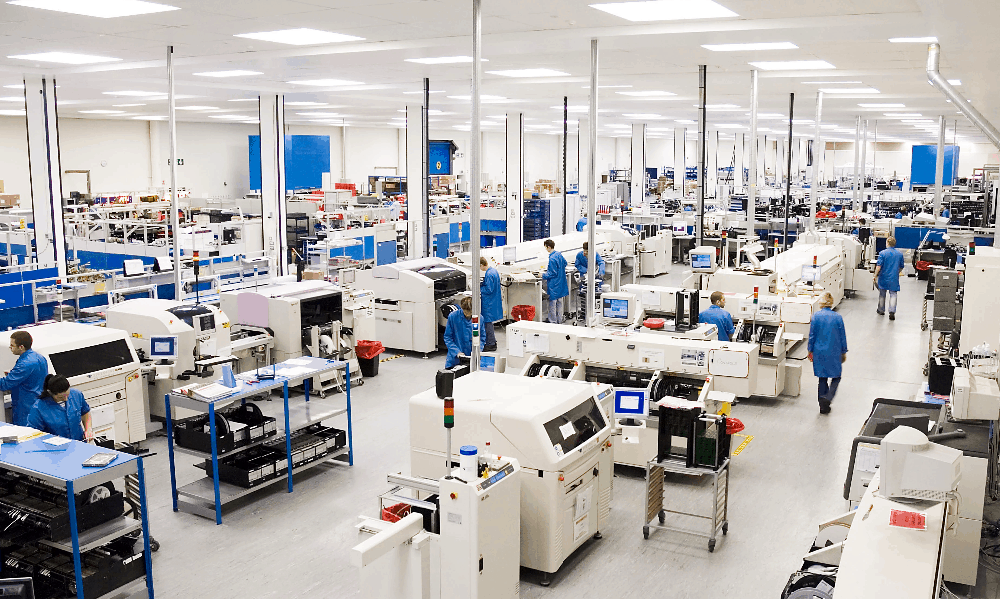

First, the PCB Assembly House is a sort of warehouse where all the relevant equipment and materials needed for the production of the Printed Circuit Boards (PCBs) are stored. It is from this “factory” of sorts that PCB manufacturers operate from.

Second, the PCB Assembly House signifies the company or the manufacturer of Printed Circuit Boards (PCBs). This implies that the company is roundly touted to be the embodiment of the PCB Assembly House.

Having said that, it is time to look at other important elements of the PCB Assembly House. This article will enlighten you enough so that you wouldn’t be confused anymore when topics relating to PCB Assembly House are brought up.

————————————————————-

Request PCB Manufacturing & Assembly Quote, Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

PCB Assembly House Equipment

There is special equipment that is used anytime you want to engage in PCB Assembly. Understandably, it can be an arduous task to select the best equipment because several factors need to be considered first.

From the quantity of the Printed Circuit Boards (PCBs) that need to be produced to the quality of the boards, you want to be sure that you are using not but the best.

To that end, we have made a list of and explained the relevant equipment, which is mainly used by PCB Assembly Houses.

- Pick and Place Machines

Automation is now leading the way in different industries and the Printed Circuit Boards (PCBs) industry is not taking the back seat. Instead, it has already geared up with the use of the relevant technologies as a way of positioning itself for greater tidings in the global industry marketplace.

That said, there is a machine that places a vital role in the PCB Assembly House. That machine is the Pick and Place Machine. Already, the name has explained what it is meant to do.

However, we shall offer more explanations so you can have a better idea of how the Pick and Place Machines work.

First, the original formulation of the Pick and Place Machines is to make sure that the PCB components are picked up from where they are packed or placed and dropped onto the Printed Circuit Boards (PCBs).

While this can be mesmerizing and tedious because of the human input formulations, there seems to be some reprieve. With the latest advancements in technology, industry analysts are looking at the best ways of incorporating automation into the Pick and Place Machines.

In the future, additional precision will be included in the Pick and Place Machines so that they can process PCB projects faster than humans would have done with the use of a pair of tweezers. This time, the machines will be programmed at once and will then continue to work in automation.

- Solder Paste Printing Machine

Solder in the Printed Circuit Boards (PCBs) industry is more of “glue” that holds the different components of the board together. Now, it is used alongside the Solder Paste Printing Machine for maximum effects.

The machine aims to aid in the even distribution of the pasts to where the components of the Printed Circuit Boards (PCBs) will finally sit.

- Reflow Soldering Machine

The Reflow Soldering Machine is advanced. It sees to the final stages of sticking or glueing the components of the Printed Circuit Boards (PCBs) to their respective pads.

In this instance, the Printed Circuit Boards (PCBs), which by now must have been filled with their respective components, will be moved into the Reflow Soldering Machine. The movement will be facilitated along a conveyor, and through a long and giant oven.

Once the Printed Circuit Boards (PCBs) are in the Reflow Soldering Machine, the boards will be made to travel through the different segments of the machine. In the course of doing, specific temperatures will be maintained in a way that ensures the even melting of the solder paste. The controlled temperature also ensures that the solder pastes later metamorphose into stronger electrical connections between the pads on the PCBs and the components therein.

- In-Circuit Testing (ICT)

The In-Circuit Testing (ICT) machine, which is also called the “Bed of Nails”, is an important machine in the PCB Assembly House. The overall significance of the machine is that it is used to instantly detect possible breaks in the continuity or shortage of electrical transmissions on the Printed Circuit Boards (PCBs).

The aim of doing this is to ensure that the PCBs are in “good condition” to avoid being brought back for reversals and modifications after they must have been released for use.

————————————————————-

Request PCB Manufacturing & Assembly Quote, Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

How To Pick the Best PCB Assembly House

We’ll like to point out an important aspect. The PCB Assembly House can also be regarded as the company that engages specifically in the Fabrication of Printed Circuit Boards (PCBs). The PCB Assembly House is also the company that specializes in offering PCB Assembly services.

Now, you want to select one out of the hundreds of PCB Assembly Companies that are operating in different parts of the world.

Because the selection process can be tough, we decided to cut the chase and make things a lot easier for you. Below are some of the important factors that will help you in finding the best PCB Assembly House.

- Quality

You want to be sure that the PCB Assembly House can deliver quality and consistent Printed Circuit Boards (PCBs).

Because quality is abstract and cannot be seen physically, we have put together some indicators that will help you make a good judgment of a PCB Assembly House’s quality of service.

- Check for the application of the Administration of Engineering Change Order (ECO).

- Find out if the PCB Assembly House conforms to the laid-down rules and regulations that are based on quality control of Printed Circuit Boards (PCBs). Some of the things to look for here are:

- The AQL Level

- The Equipment Calibration

- The Material Inspection Record

- The Bill of Materials (BOM) Preservation

- The SMT Yield Rate and

- The ESD Implementation.

- Equipment

We already discussed some of the important equipment that needs to be available for the success of Printed Circuit Boards (PCBs) manufacturing.

Therefore, the PCB Assembly House you want to patronize ought to have the relevant equipment that is needed for the success of the PCB project you have at hand.

Some of the important equipment you should look out for are:

- The Pick and Place Machines

- PCB Stencil

- X-Ray Inspector

- In-Circuit Testing (ICT) Machine

- Automated Optical Inspection (AOI) Machine

- Solder Paste Inspection (SPI) Machine to check the thickness of the Solder Paste.

- Industry

Another important factor for selecting a PCB Assembly House is to find out the industry where it specializes. Because Printed Circuit Boards (PCBs) are needed in many industries, you must work with the company that can meet your needs.

The PCB Assembly House is versed in the relevant components that are needed for the success of your PCB project. That’s why you want it to handle the sourcing of components.

To that end, check to see if the PCB Assembly House you intend using has a component sourcing service, which allows the company to source the needed components for the PCB projects.

- Cost

You want to save costs. That can also be a determining factor in the PCB Assembly House you’ll use in the end.

Here, we are looking at the costs from two perspectives.

First, the PCB Assembly House may offer you higher costs for some reasons. It could be that you are ordering smaller units of PCBs. It can also be because of the one-off order type, which means you aren’t returning for another transaction.

On the other hand, there is a potentiality to reduce costs. You can negotiate this by requesting a discount for subsequent orders.

Second, the cost can be influenced by hidden charges. The actual cost of the PCB project may be affordable but you weren’t intimated with other underlying costs.

For that reason, we advise that you should make sure that the price tag you receive from the salesperson is the final cost.

Final Words

The PCB Assembly House is responsible for the successful manufacturing of Printed Circuit Boards (PCBs).

Considering that you may have different specifications for your Printed Circuit Boards (PCBs), we put together the above tips to guide you.

We are hopeful that you have gained considerable insights into what to look for when you want to make use of a PCB Assembly House for your high volume PCB projects.

Comments are closed