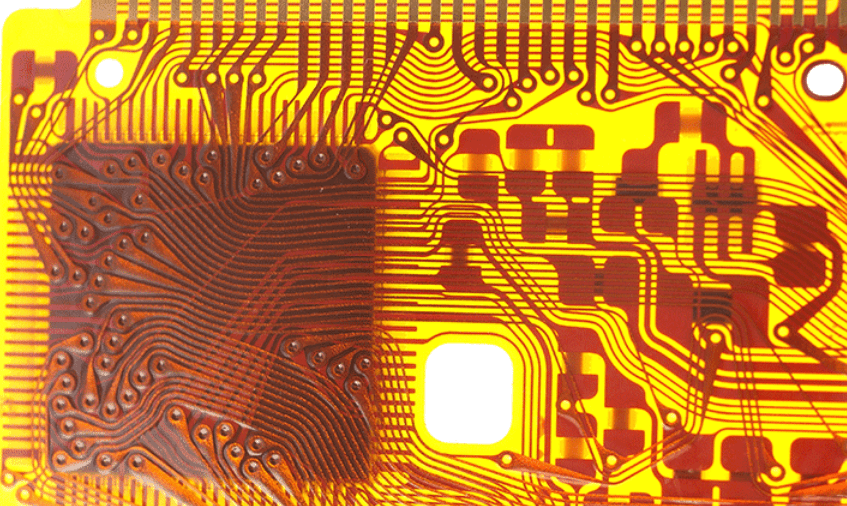

PC board flex, also known as flexible printed circuit boards (FPCBs), is a technology that has been around for decades. However, it has gained popularity in recent years due to its unique features and advantages over traditional rigid PCBs. FPCBs are thin, lightweight, and flexible, making them ideal for applications where space is limited or where the board needs to conform to a specific shape or contour. Additionally, FPCBs are highly reliable and durable, making them suitable for use in harsh environments.

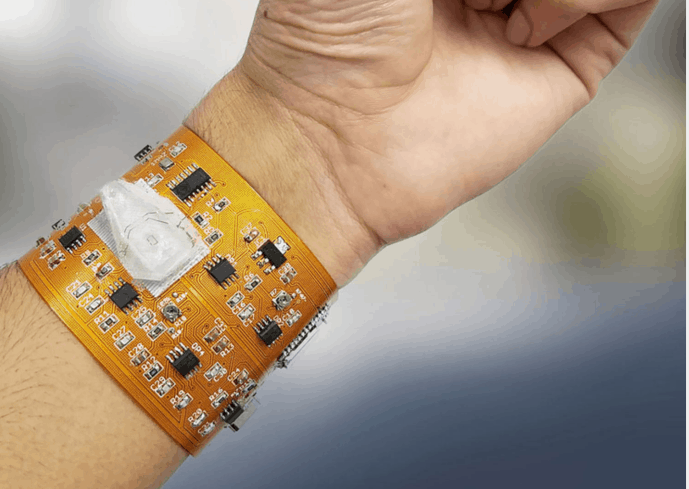

One of the main benefits of FPCBs is their ability to reduce the size and weight of electronic devices. By using FPCBs, manufacturers can design smaller and thinner devices, which is particularly important in industries such as mobile phones, wearables, and medical devices. FPCBs can also be bent or folded, allowing for more complex designs and greater flexibility in product development.

Despite their advantages, FPCBs also present some challenges. For example, designing and manufacturing FPCBs requires specialized knowledge and equipment, and the cost can be higher than traditional rigid PCBs. Additionally, FPCBs may be more susceptible to damage from bending or flexing, and the use of certain components may be limited due to the board’s flexibility. Nonetheless, the benefits of FPCBs make them a valuable technology for a wide range of applications, and their use is expected to continue to grow in the coming years.

What is a PC Board Flex?

A PC board flex, also known as a flex circuit or flexible printed circuit board, is a type of electronic circuit board that can bend and flex without breaking. It is made up of a thin, flexible substrate material, such as polyimide or polyester, which is coated with a layer of conductive material, usually copper.

Flex circuits are commonly used in electronic devices where space is at a premium or where the circuit board needs to bend or flex to fit the design of the device. They are often found in applications such as smartphones, tablets, and wearable devices.

Flex circuits can be single-sided, double-sided, or multilayered, depending on the complexity of the circuit. They can also be designed to have different types of connectors, including edge connectors, ZIF (zero insertion force) connectors, and FPC (flexible printed circuit) connectors.

One of the benefits of using a flex circuit is that it can reduce the overall size and weight of the device, as well as increase the reliability of the circuit. Flex circuits also offer greater design flexibility than traditional rigid circuit boards, as they can be shaped and molded to fit the specific needs of the device.

However, flex circuits can be more expensive to manufacture than rigid circuit boards, and they may not be as durable over the long term. It is important to carefully consider the specific needs of the device before deciding to use a flex circuit.

Types of PC Board Flex

Single-Sided Flex

Single-sided flex PCBs are the simplest type of flex PCB. They have a single layer of conductive material, usually copper, on one side of the flexible substrate. These PCBs are ideal for applications that require low-density circuitry and a small number of components. Single-sided flex PCBs are also the most cost-effective type of flex PCB.

Double-Sided Flex

Double-sided flex PCBs have two layers of conductive material on either side of the flexible substrate. These PCBs are used when the circuitry is more complex and requires more components. Double-sided flex PCBs are more expensive than single-sided flex PCBs, but they are still relatively cost-effective compared to rigid PCBs.

Multilayer Flex

Multilayer flex PCBs have multiple layers of conductive material and flexible substrate. These PCBs are used when the circuitry is even more complex and requires a large number of components. Multilayer flex PCBs are the most expensive type of flex PCB, but they offer the highest level of performance and reliability.

In addition to the types of flex PCBs, there are also different types of flexing that can occur in these PCBs. These include dynamic flexing, which occurs when the PCB is repeatedly bent or flexed, and static flexing, which occurs when the PCB is flexed once and then remains in that position.

Overall, the type of flex PCB chosen will depend on the specific requirements of the application.

Design Considerations for PC Board Flex

Bend Radius

The bend radius of a flexible PCB is one of the most important design considerations. The bend radius is the minimum radius that the flexible circuit can be bent without damaging the conductive traces. The bend radius is determined by the thickness and type of the flexible material, as well as the thickness of the copper traces. It is important to choose a bend radius that is appropriate for the specific application.

Trace Width and Spacing

The trace width and spacing of a flexible PCB are also important design considerations. The width and spacing of the traces must be chosen based on the current-carrying capacity of the circuit and the voltage requirements of the application. It is important to ensure that the traces are wide enough to carry the required current without overheating, and that the spacing between the traces is sufficient to prevent arcing.

Stackup Design

The stackup design of a flexible PCB is another important consideration. The stackup design determines the number of layers in the circuit, as well as the order and type of the layers. The stackup design must be chosen based on the specific application requirements, such as signal integrity, power distribution, and thermal management.

Connector Selection

The selection of connectors for a flexible PCB is also an important consideration. The connectors must be chosen based on the specific application requirements, such as the number of connections, the type of signal being carried, and the environmental conditions. It is important to choose connectors that are reliable, easy to use, and compatible with the flexible material and copper traces.

In summary, the design considerations for PC board flex include bend radius, trace width and spacing, stackup design, and connector selection. These considerations must be carefully chosen based on the specific application requirements to ensure the reliability and performance of the flexible PCB.

Applications of PC Board Flex

Consumer Electronics

PC board flex is widely used in consumer electronics such as smartphones, tablets, and laptops. The flexibility of the board allows for a compact design, which is essential for these devices. The use of flex boards also provides improved durability and shock resistance, which is important for devices that are frequently dropped or subjected to other impacts.

Medical Devices

Flex boards are also used in medical devices such as pacemakers, hearing aids, and insulin pumps. The flexibility of the board allows for a smaller design, which is important for implantable devices. The use of flex boards also provides improved reliability, as there are fewer connections that can fail.

Aerospace and Defense

The aerospace and defense industries also make use of flex boards in applications such as satellites, missiles, and aircraft. The flexibility of the board allows for a more compact design, which is important for these applications where space is at a premium. The use of flex boards also provides improved reliability, as there are fewer connections that can fail.

Overall, the use of PC board flex provides many benefits in a variety of applications. Its flexibility allows for a more compact design, improved durability and shock resistance, improved reliability, and more.

Advantages and Disadvantages of PC Board Flex

Advantages

PC board flex has several advantages that make it a popular choice for many applications. These include:

-

Space-saving: PC board flex allows for compact designs that can fit into tight spaces. This is because the flexible nature of the board allows it to bend and conform to the shape of the device it is being used in.

-

Reduced weight: Because PC board flex is thinner and lighter than traditional rigid PCBs, it can help reduce the overall weight of a device. This can be especially important in applications where weight is a critical factor, such as aerospace or medical devices.

-

Improved reliability: PC board flex can be more reliable than rigid PCBs because it has fewer interconnects and solder joints, which can be points of failure. Additionally, the flexible nature of the board can help absorb shock and vibration, which can help prevent damage to the board and the components it contains.

Disadvantages

While PC board flex has many advantages, it also has some disadvantages that should be considered. These include:

-

Higher cost: PC board flex can be more expensive than traditional rigid PCBs due to the additional manufacturing processes required.

-

Limited flexibility: While PC board flex is flexible, it does have limits to how much it can bend and flex. This can be a disadvantage in applications where the board needs to be able to bend and flex significantly.

-

Design challenges: Designing with PC board flex can be more challenging than designing with rigid PCBs. This is because the flexible nature of the board can make it more difficult to route traces and place components.

In summary, PC board flex offers several advantages such as space-saving, reduced weight, and improved reliability. However, it also has some disadvantages such as higher cost, limited flexibility, and design challenges.

Future of PC Board Flex Technology

PC board flex technology has come a long way over the years, and it continues to evolve. Here are a few trends that we expect to see in the future of PC board flex technology.

Thinner and More Flexible

As technology advances, we can expect to see PC board flex technology become even thinner and more flexible. This will allow for even more compact and lightweight devices, especially in the wearables and mobile devices markets.

Higher Density

As devices become smaller, the need for higher density PC board flex technology will increase. This will require advancements in manufacturing processes to ensure that the high-density circuits can be produced reliably and cost-effectively.

Integration with Other Technologies

As the Internet of Things (IoT) continues to grow, we can expect to see more integration between PC board flex technology and other technologies such as sensors, wireless communication, and energy harvesting. This will enable the development of even more innovative and useful devices.

Improved Durability

One of the biggest challenges with PC board flex technology is ensuring that it is durable enough to withstand the rigors of everyday use. In the future, we can expect to see improvements in the materials and manufacturing processes used to create PC board flex technology, resulting in even more durable and reliable devices.

Conclusion

PC board flex technology has come a long way, and it continues to evolve. As technology advances, we can expect to see thinner and more flexible PC board flex technology, higher density circuits, integration with other technologies, and improved durability. These advancements will enable the development of even more innovative and useful devices in the future.

Comments are closed