Printed Circuit Boards (PCBs) are the backbone of electronic devices. PCBs provide the physical foundation for the various electronic components that make up a circuit. As such, PCBs are critical components in the manufacturing process of electronic devices. However, PCB assembly can be an expensive and time-consuming process, making it a challenge for manufacturers to balance quality, cost, and time to market. Low cost PCB assembly is essential to addressing this challenge. We will discuss the importance of low cost PCB assembly and how it can benefit manufacturers and end-users alike.

One of the most significant benefits of low cost PCB assembly is the reduction in manufacturing expenses. PCB assembly typically accounts for a significant portion of the total manufacturing cost of electronic devices. By reducing the cost of PCB assembly, manufacturers can increase their profit margins and make products affordable for consumers. This is especially important in today’s highly competitive electronics market, where consumers have many options to choose from. By offering products at lower prices, manufacturers can attract more customers and gain a competitive advantage.

Low cost PCB assembly can also help manufacturers reduce the time it takes to bring their products to market. With traditional PCB assembly methods, the time required to manufacture and assemble PCBs can be lengthy. It can further delay the launch of new products. By using low cost PCB assembly techniques, manufacturers can streamline the manufacturing process. And they can reduce the time it takes to get their products to market. This allows manufacturers to capitalize on new trends and emerging technologies faster. It can be critical in the fast-paced world of electronics.

Another significant benefit of low cost PCB assembly is the ability to improve the quality of the final product. Lower costs often result in more significant investments in research and development, equipment, and training. This investment can lead to the development of more advanced manufacturing processes, which can result in higher quality PCBs. Improved quality can lead to increased product reliability, better customer satisfaction, and lower warranty claims. All of these are critical factors for manufacturers and end-users alike.

Furthermore, low cost PCB assembly can contribute to sustainability efforts. As PCBs become more affordable, more manufacturers can use them, which can result in a lower overall environmental impact. Additionally, low cost PCB assembly techniques often involve using fewer materials and generating less waste. So, it can also contribute to sustainability efforts.

Designing of Low Cost PCB Assembly

Designing PCBs for low cost assembly is essential to ensure that the manufacturing process is as cost-effective as possible. PCB design affects the cost of assembly in several ways, including the complexity of the design, the type of components used, and the layout of the board. Here we will discuss some of the key factors to consider when designing PCBs for low cost assembly.

1. Design for Manufacturability

Designing for manufacturability (DFM) is a crucial concept to consider when designing PCBs for low cost assembly. DFM involves designing the PCB in a way that is optimized for the manufacturing process. Designing the PCB with standard sizes can make it easier to manufacture and reduce the cost of materials. Other DFM considerations include the placement of components, the layout of the board, and the use of standard components. By designing the PCB with manufacturability in mind, you can ensure that the manufacturing process is cost-effective.

2. Component Selection

Component selection is another critical factor to consider when designing PCBs for low cost assembly. Choosing the right components can have a significant impact on the overall cost of the PCB assembly. When selecting components, it’s important to consider factors such as cost, availability, and reliability. Additionally, using standard components can help reduce costs by making it easier to source parts. And it reduces the need for customization. However, it’s essential to balance the cost of the components with the functionality and performance of the final product.

3. Board Layout

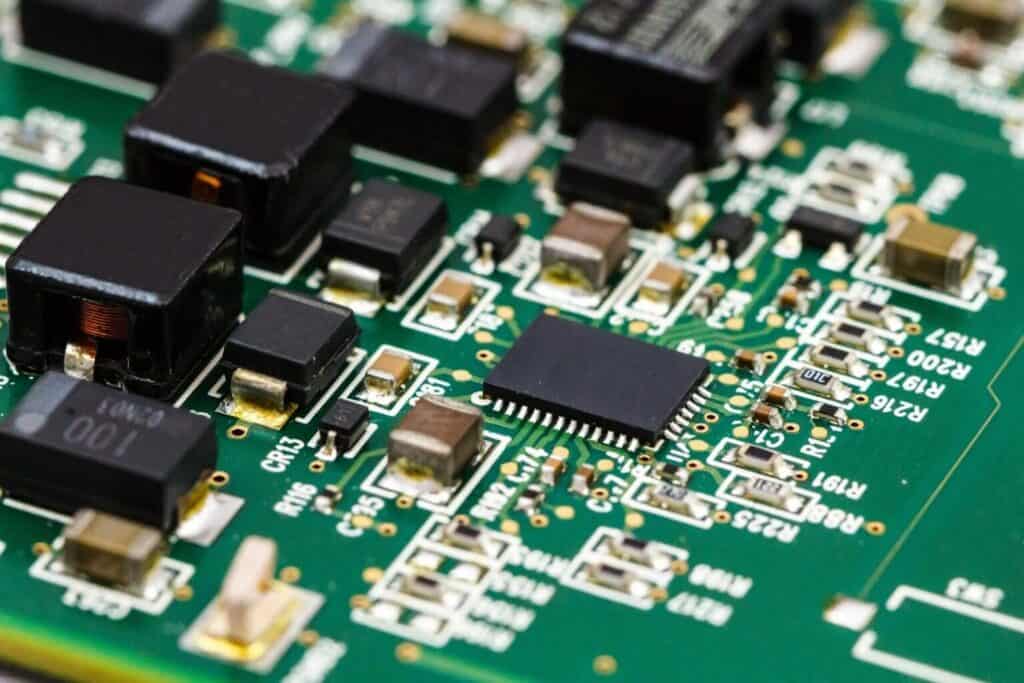

The layout of the PCB can also impact the cost of assembly. A well-designed layout can help reduce the number of components needed, simplify the manufacturing process, and minimize waste. For example, placing components close together can reduce the length of the traces and the size of the board. These factors can reduce the cost of materials. Additionally, using a single-sided PCB design can help reduce the cost of assembly by simplifying the manufacturing process.

4. Trace Width and Spacing

The width and spacing of the traces on the PCB can also impact the cost of assembly. Narrow traces and tight spacing can make the manufacturing process more challenging and increase the likelihood of errors. On the contrary, wider traces and wider spacing can make the manufacturing process less prone to errors. Therefore, it’s important to balance the need for functionality with the cost of manufacturing when designing the PCB.

5. Testing and Debugging

Testing and debugging are critical parts of the manufacturing process. And they can significantly impact the overall cost of assembly. Designing the PCB with testing and debugging can help reduce the cost and time required for these processes. For example, adding test points to the PCB can make it easier to test the board and diagnose issues. It can reduce the time required for testing and debugging.

Selection of the Right Components for Low Cost PCB Assembly

Selecting the right components for low cost PCB assembly is an essential aspect of PCB design. The cost of components can account for a significant portion of the overall cost of PCB assembly, so it’s important to carefully consider the choice of components to optimize cost without sacrificing quality or performance. In this paper, we will discuss the factors that influence component selection and how to choose the right components for low cost PCB assembly.

1. Performance and Functionality

One of the most critical factors to consider when selecting components is performance and functionality. The components chosen must be able to meet the performance requirements of the final product. Therefore, it’s essential to consider the specifications of the components. These include voltage ratings, power ratings, frequency range, and other performance parameters. Choosing components with higher performance than required can lead to unnecessary costs. On the contrary, selecting components with lower performance can lead to inadequate functionality and reliability.

2. Cost

Cost is another critical factor to consider when selecting components for low cost PCB assembly. Choosing low-cost components can help reduce the overall cost of PCB assembly. However, it’s important to balance cost with performance and quality. It’s essential to consider the cost of the component itself. Moreover, consider, any additional costs associated with sourcing the component, such as shipping or import duties. Additionally, it’s important to consider the cost of any necessary testing or calibration of the components.

3. Availability

Availability is another critical factor to consider when selecting components for low cost PCB assembly. It’s essential to choose components that are readily available and can be sourced from multiple suppliers. Choosing components that are difficult to source can lead to delays in the manufacturing process. Furthermore, it will increase costs associated with sourcing components from multiple suppliers. Therefore, it’s important to consider the availability of the components before making a final decision.

4. Reliability

Reliability is another crucial factor to consider when selecting components for low cost PCB assembly. The components chosen must be reliable and able to perform under the expected conditions of use. Choosing components with a reputation for reliability can help reduce the likelihood of component failure. Moreover, it increases the overall quality and longevity of the final product. It’s essential to consider factors such as the expected lifespan of the component, the operating temperature range, and the expected conditions of use when evaluating the reliability of a component.

5. Size and Package

The size and packaging of the components can also impact the cost of PCB assembly. Smaller components which are closer together can help reduce the size and cost of the PCB. Additionally, choosing components with standard package sizes can help reduce costs associated with customization. Moreover, it can make it easier to source and assemble the components. However, it’s important to ensure that the size and packaging of the components do not compromise performance or reliability.

6. Compatibility

Compatibility is another critical factor to consider when selecting components for low cost PCB assembly. It’s essential to ensure that the chosen components are compatible with the rest of the system. Additionally, they are compatible with the manufacturing process. For example, some components may require special handling or assembly techniques that can increase the cost of PCB assembly. Additionally, it’s important to consider the compatibility of the components with the software and firmware of the system.

7. Future Availability

Finally, it’s important to consider the future availability of the components when selecting components for low cost PCB assembly. Components that are expected to become obsolete or difficult to source in the future can increase the long-term cost. Therefore, it’s important to choose components that are available for the expected lifespan of the final product.

Future of Low Cost PCB Assembly Techniques

The evolution of PCB assembly technology has significantly impacted the growth of the electronics industry. It has increased at a rapid pace in the past few decades. With the increase in demand for electronic devices, the need for cost-effective PCB assembly techniques has become critical. This section will discuss the future of low-cost PCB assembly techniques and how they will shape the electronics industry in the years to come.

Current State of PCB Assembly Techniques

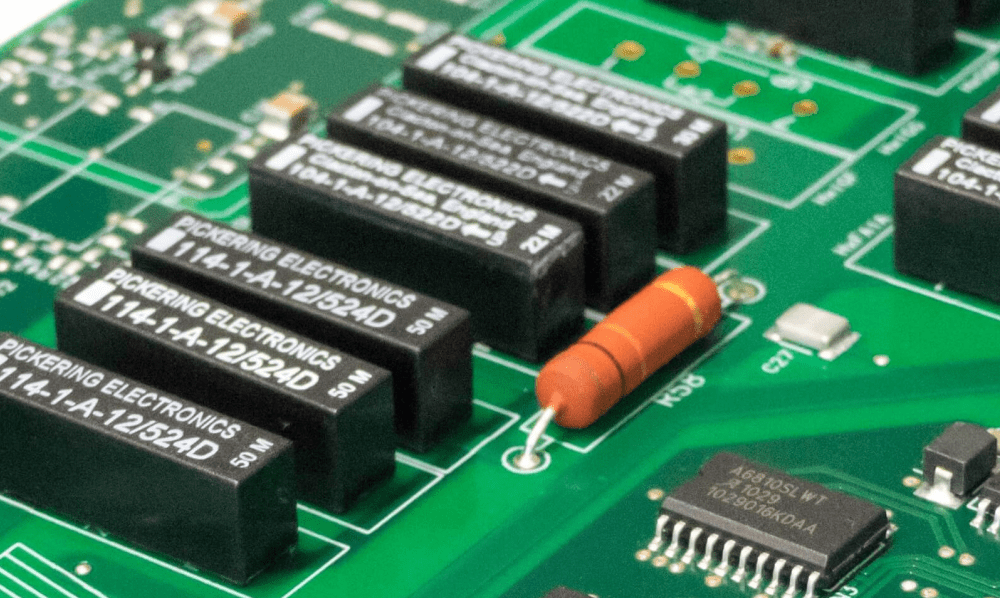

The current state of PCB assembly techniques is largely based on Surface Mount Technology (SMT). SMT has been the dominant technology for several decades. SMT involves mounting electronic components on the surface of the PCB, rather than through-hole mounting. And it is an older technology that involves mounting components through holes drilled in the PCB. SMT allows for higher component density, smaller PCBs, and higher production volumes. However, SMT can be expensive, and the process can be complicated, especially for small-scale production.

Future of Low-Cost PCB Assembly Techniques

The future of low-cost PCB assembly techniques is exciting. This is because several emerging technologies have the potential to revolutionize the electronics industry. Here are some of the key technologies that are expected to drive the future of low-cost PCB assembly techniques.

· 3D Printing

3D printing has the potential to revolutionize the manufacturing industry, and PCB assembly is no exception. With 3D printing, it is possible to create complex PCBs with built-in components. Further it eliminates the need for surface mounting or through-hole mounting. This technology has the potential to significantly reduce production costs, as well as the time required to manufacture PCBs.

· Printed Electronics

Printed electronics is a new technology that involves printing conductive inks onto flexible substrates, such as plastic or paper. This technology allows for the creation of flexible, lightweight, and low-cost electronic devices, including PCBs. Printed electronics have the potential to replace traditional PCBs, as well as create new applications, such as wearable devices.

· Artificial Intelligence (AI) and Robotics

We expect AI and robotics to play a significant role in the future of low-cost PCB assembly techniques. With AI, it is possible to optimize production processes and reduce costs by identifying inefficiencies and improving workflows. We can use robotics to automate the PCB assembly process. Furthermore, it will reduce the need for human labor and increasing production efficiency.

· Challenges and Opportunities:

While the future of low-cost PCB assembly techniques is promising, there are also several challenges that need special attention. One of the biggest challenges is ensuring that the new technologies are reliable and produce high-quality products. Another challenge is the need for skilled workers who can operate and maintain the new equipment. There is also the challenge of ensuring that the new technologies are environmentally friendly and sustainable.

Despite these challenges, there are several opportunities that arise with the development of low-cost PCB assembly techniques. For example, low-cost PCB assembly techniques can drive innovation and create new markets. Additionally, low-cost PCB assembly techniques can help to bridge the digital divide by making technology more affordable to people.

Comments are closed