LED lighting has revolutionized the lighting industry. LED PCBs can now be found just about anywhere you need them, and they’re a much better choice than other types of lighting. With the growing demand for this technology, it’s constantly evolving to keep up with demand.

When the LED lighting PCB Assembly was revolutionalized, there was an increase in demand for LEDs. The new PCB’s are more robust, durable, and perform better than the previous models. Also, people are choosing LED lights over fluorescent or incandescent lights. The latter caused a lot of heat which initially made them unpopular.

The PCB couldn’t handle the high temperatures for long, so the LEDs were affected as well. But thanks to the metal core PCB, heat dissipation won’t be a problem. They remove heat without using heat sinks. Aluminum PCBs are really popular because they both keep costs low and offer excellent performance.

What Exactly Is LED?

LED is written fully as Light Emitting Diode. Light emitting diodes (LEDs) are semiconductor device that emits visible light, making them perfect for lighting. LEDs emit a unique type of light and can be used in almost any location

LED lights can now be found in nearly every sector and industry for general lighting, to indicate everything from parking spaces to alarm levels. Because of its versatility, the LED industry is booming.

What Does LED PCB Mean?

LED PCBs are circuit boards that are useful in the manufacturing of LED fixtures. High power LEDs usually generate much heat, which is why aluminum is often used as their substrate material. The thermal conductivity of aluminum helps to dissipate that heat and simplify the circuitry required to turn LEDs on or off.

With an LED Printed Circuit Board, the printing of the circuit is done on the aluminum plane having great thermal conductivity. Then the soldering of the electronic components take place.

LEDs are being used in a wide range of circuits, and there are many factors that affect the quality of PCB production. The main variables are the thickness, aluminum model, surface treatment, hardness, and others. These can vary depending on what heat the product needs

What Does LED Lighting PCB Assembly Mean?

A PCB assembly is a board with all components mounted on it. It may also be called an LED lighting PCB assembly if it will be used for lights. For example, an LED lighting PCB assembly will contain LEDs coupled with other components.

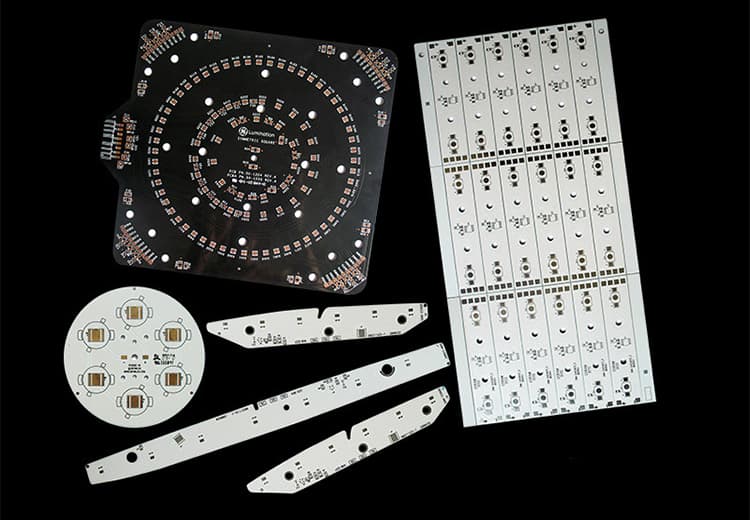

Aluminum is used in an assembly to remove heat faster. The aluminum is durable and won’t break easily. It can withstand wears for long periods, so it’s a reliable material for installation purposes. These options are perfect for when the buyer needs the specific shape of an assembly. Circular or rectangular circuit boards make up many options, while LED PCB strips are also popular.

An LED lighting PCB assembly includes the creation of a PCB as well as installing the components. This is a lengthy procedure that includes each step. The turnkey PCB assembly is one in which the contract manufacturer is responsible for everything.

Why LED PCB Assemblies and LEDs are Important

Compact LEDs are small, making them perfect for use in tight spaces. They are useful in small spaces whereby it is difficult to fix incandescent light bulbs. They can also be integrated into a complicated PCBAs because they take up very little space.

LED PCB are very compact, and they offer a lot of design flexibility. These boards can be arranged in any configuration desired.

Incandescent and fluorescent lighting lose their effectiveness after only a few thousand hours, but LEDs last up to 25x longer, meaning they don’t have to be replaced as often. As a result, they save people money.

The LED lights have a long life due to their ability to dissipate heat effectively and don’t need heating to give light. Compared to other electrical devices, LED lights are better because they do not waste energy. They help emit light whenever current flows into them, and there is little loss of energy loss

Meanwhile, other technologies have hazardous mercury as well as toxic substances that can affect the environment negatively. A more environmentally-friendly solution is LED lighting. No toxins used in producing LED lighting PCB assembly and this is why it is safe for the environment.

LEDs are the safest choice for your indoor lighting because they require low voltage. They’re also better for your home’s energy usage and provide safety features such as an open circuit, which is when the circuits are violated by a short circuit, receptacle disconnection, or other causes.

There is no ambient temperature effect. LED PCB Lighting Assemblies can be used in any environment. The pcb assembly is designed for a variety of applications and could withstand extreme temperatures.

Process of LED Lighting PCB Assembly

In the manufacturing process, LED lighting PCB Assembly steps are similar to many other circuit board assemblies. It consists of several steps.

Order Placement

First of all, the customer will place an order once done discussing the assembly requirements. Then he/she will provide all necessary documents and files. Following that, the Design for Manufacturability is conducted. It is required to ensure the whole process possible.

At Hillman Curtis, our experts inspect the files that are provided by a buyer for errors. Before we begin the process, we double-check everything.

Fabrication of the PCB

Because components are usually placed on a board, the PCB must be created in the initial step. The PCB for LED lighting PCB assembly is made from aluminum. This is a great material for heat dissipation and durability. Three layers are present in an aluminum PCB.

Its copper layer serves electrical connections and it is the PCB’s first layer. The 2nd layer is made of dielectric material. This is in charge of heat transfer that is generated by LEDs. Also, the aluminum base layer is the final layer.

The fabrication of this PCB is done in accordance with the buyer’s specifications.

Components Acquisition

The components needed for the PCB is ordered from various vendors. The step requires time and could take 3 to 5 days. This depends on components needed. The components are arranged in the order specified in the BOM. The resistors, SMD LEDs, as well as other components are purchased.

Applying Solder Paste to the PCB

To connect all the components to the board, solder paste is used. The solder paste is initially applied to an empty PCB making use of a stencil. This stencil aids in applying paste to appropriate areas. A wiper is used to apply the paste. The wiper also applies the solder paste and cleans up any excess. The paste is useful for the placement and soldering of SMDs.

Picking and Placing the components

Now you can place your components on the PCB after the paste has been applied. This process is an automated one performed by a machine. A file is used to provide instructions to a machine.

Reflow Soldering

Here, your PCB is then passed via a specific reflow oven. Because of the heat present in the reflow oven, that solder melts which forms a sort of connection between the components and the board. Because the circuit board is still hot after melting, it is then cooled before being removed from the oven.

SMDs are soldered using reflow soldering. If there is any through-hole component, they are all hand soldered. If it is a one-sided PCB, wave soldering could be useful and quick. Application of molten solder is done at the PCB’s base or bottom during wave soldering.

Inspection

After soldering, the PCB can have a variety of issues. There could be a short circuit, a missing joint, as well as other issues that need to be checked. Inspection is a critical step in ensuring the LED lighting PCB assembly performance.

In the initial step, it is done manually. The AOI can then detect flaws. There are several cameras at various angles to photograph your PCB assembly. Also, AOI is a fast process, which analyzes and detects problems thoroughly.

X-ray inspection also, is a more advanced method than the AOI. It is capable of observing connections beneath the components. After reflection, the rays pass through your PCB assembly, which then creates an image. Methods of image processing are then used to analyze the images.

Final Examination

Even when everything passes the final examination and inspection, the PCB’s results are not ensured. The LED lighting PCB assembly is subjected to a final testing to ensure proper operation and expected results. This testing is done using a variety of methods, including flying probe testing, functionality testing, and reliability testing.

Why SMD LEDs Used For LED Lighting PCB Assembly?

SMD component is extremely small and can be placed easily on the circuit board and then soldered making use of reflow soldering. This procedure is straightforward and takes little time. Also, the SMD LED is much smaller compared to the through-hole LEDs. Also, they provide design flexibility for the LED lighting PCB assembly.

Though the SMD LED is small, they have a high lumen output. This is why they are popular. Furthermore, they use less energy. Because these LEDs come with three colors (Blue, Green, and Red), any color is possible with this combination.

Small connectors are located on the two ends of SMD LEDs. These connectors connect the board’s component.

LED Lighting PCB Assembly Applications

The LED lighting PCB assembly technique has been used in the assembly of telecommunications, automotive, computer, and medical equipment.

So, in this chapter, we’ll take a closer look at these applications.

Telecommunications equipment manufacturers

LED lighting PCB assembly is useful for the manufacturing of different telecommunications equipment. This is due to the LED lighting PCB assembly being mounted with aluminum. Aluminum aids in heat transfer and dissipation, which is essential for these machines and equipment.

Automobile Manufacturing Industries

Aluminum LED PCB is used in the manufacture of brake lights, headlights, and indicators in automobiles. LED PCB is useful in the automotive industry because the aluminum component makes these parts long-lasting.

Companies involved in the Manufacturing of computers

LED lighting PCB assembly has recently piqued the interest of computer manufacturers. Computers, particularly the power unit and CPU, are extremely sensitive to heat. These components necessitate a material that can efficiently transfer and dissipate heat, making LED PCB the best choice.

Medical supplies

High-powered LED lights are used in surgical and medical examination equipment. As a result, they must be able to dissipate as well as transfer high heat, which makes LED Lighting PCB assembly the most appropriate option.

LED Lighting PCB Requirements

When working on LED lighting, it would be beneficial if you did not produce subpar results. This is because the work is very sensitive, and then one must pay serious attention to every detail. Also, PCB assembly has started gaining popularity. Also, with lights becoming smaller each passing day, there is much thought put into their perfection. The following items are required to create proper LED lighting:

To begin, when handling LED Lighting PCB assembly, you must have the necessary expertise because even minor mistakes can cause the PCB stop working. It can also lead to short circuits.

Make sure you have high-quality soldering material on hand, as this will make sure that the work is done neatly and with no errors.

Make certain that all of documents are of high quality. This ensures you make your PCB lighting stable and durable.

Due to the very high heat that you will be exposed to while working, you have to take more preventive measures to achieve precise results.

Proper lighting and technology knowledge is also required. Proper education ensures that you keep up with technology and any changes that may be required at any point in time.

Conclusion

PCB has evolved into tiny, sophisticated and multilayered systems, which bear little resemblance to their predecessors. This high sophistication also resulted in high efficiency, resulting in faster and slimmer devices. Finding the right partner to collaborate with, will save you money and time, and we are here for you.

Hillman Curtis has vast experience and certification in offering LED lighting PCB Assembly useful for a variety of purposes. Contact us right away.

Comments are closed