The manufacturing phases of electronic appliances demand the input of Printed Circuit Boards (PCBs). These are the boards that help in connecting the relevant electrical parts of the electronics.

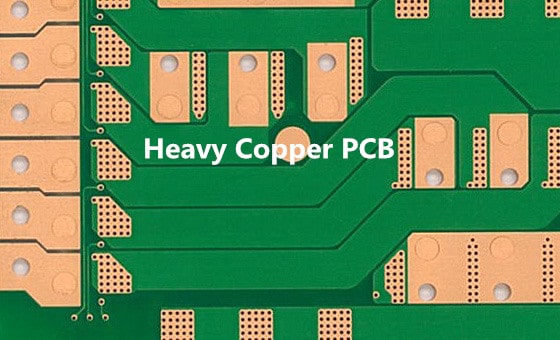

Now, the focus is on the varieties of PCBs out there. With the options readily available, electronics brands are always looking for the best. The heavy copper PCB happens to be one of the most used forms of the Printed Circuit Boards (PCBs).

You may have some heavy copper PCB questions too as those will help you understand how the board works. We have taken the time to create this content to capture the important aspects of the extreme copper PCB.

————————————————————-

Request Heavy Copper PCB Quote, Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

What Is Heavy Copper PCB?

We would first like to point out that there is no concrete or specific definition of the heavy copper PCB. Rather, the use cases have tremendously helped in the comprehension of how it works.

The heavy copper PCB is the type of Printed Circuit Board (PCB) that has more thickness and components than the regular PCB does.

There are two variations in the definition of the heavy copper PCB. Below are those variations and how they work:

Sheet of Copper

The first component is the sheet of copper that the board has. Ideally, the traditional heavy copper PCB is the type that has up to 85 grams of copper or three ounces of copper.

This is usually located in the internal and external layers of the PCB.

Extreme Copper PCB

In some other cases, there are times when the PCB design will be advanced. That is the case that triggers the second variation – the extreme heavy copper.

The PCB copper thickness associated with this is up to 10 Oz for every ft2. When it comes to the inner and outer layers, the copper thickness or deposition is about 200 Oz for every ft2.

Heavy Copper PCB Features

You now know about the types of thicker and heavy PCB designs. Let us now look at the features and properties of such Printed Circuit Boards (PCBs).

Heavy Copper Plated Holes

The first feature is the number of copper holes. This is the case when more PCB plated holes are used to thicken the copper.

Reliable Wiring

Wiring and connecting the electrical components doesn’t prove difficult when using the heavy copper PCB design.

All there is to do is to combine the copper weight with an appropriate substrate. That is the reason why the thicker plating used in the through-hole circuit is very active.

Benefits of Heavy Copper PCB

We would like you to understand the benefits of the heavy copper PCB design before you look for a manufacturer to handle the job.

Do you have some things to gain when your next Printed Circuit Board (PCB) design is made of heavy copper?

Let’s find out!

1. More Loads

For many years now, electronics manufacturers have been wondering if there is a way to make their PCBs to handle more loads.

There is no more downplaying the importance of the heavy copper model of designing PCBs because it can handle more loads. It is because of the higher and efficient current carrying capacity that enables the more loads the PCB can handle.

1. Less Wiring Complications

The second benefit of PCB copper thickness is the less complicating wiring processes.

You wouldn’t have to bother about the fussy wiring that could have rendered the configuration distorting.

2. More Resistance and Endurance

The era of limited endurance of the Printed Circuit Board (PCB) is gone. This time, the more copper layer of the heavy PCB design ensures that the resistance and endurance levels are high.

Besides, the higher resistance is channeled in the area of using the copper-plated vias to provide more resistance to the high thermals.

On the other hand, the endurance of the heavy copper Printed Circuit Board (PCB) is measured in terms of the feasible use even in higher temperatures.

3. Improved Mechanical Features

The mechanical features and characteristics are another reason why the extreme copper PCB is gaining traction.

The importance of this model is that the exotic materials used in the design will dramatically improve the mechanical components of the PCB.

4. More Mechanical Power

You should also be expecting more mechanical power. This is partly because of the improvements in the connector sites and mainly because of the PTH holes.

5. Compact

As much as the heavy copper PCB design may be considered heavier, that isn’t always the case.

Instead, it has a compact and small size because of the integration of all the components into one PCB.

————————————————————-

Request Heavy Copper PCB Quote, Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

How to Select the Best Heavy Copper PCB Manufacturer

Your quest to have a heavy copper PCB can only be possible if you outsourced the job to a manufacturer that understands how to handle it.

We want the entire fabrication, design, and manufacturing process to be easy for you. That informs the reason why we made the guide below to help you find out the best manufacturer for the job:

1. Mass Production

The manufacturer that offers mass production should be among the first you must consider. There are many reasons why you should prioritize the same.

Here are the benefits of selecting a Printed Circuit Board manufacturing factory that offers mass production of PCBs:

Excellent Handling of Workloads

Because the manufacturer will have more loads to handle, you should ensure that the same can be completed in real-time.

The benefit thereof is that if the manufacturer can complete the job in a few weeks, it means you can rely on it. That way, when you have multiple heavy copper PCB orders, you already know who will handle it better.

The other benefit is that the more jobs are handled, the lower the costs you will pay. Ideally, the PCB manufacturer tends to give some discounts when you have many boards to be designed and manufactured.

2. Reputation

Reputation is the lifeblood of every business is a phrase we have come to understand in the business clime. It means that a company that has the trust and confidence of the customers tends to attract more customers.

As a client looking for the best heavy copper PCB manufacturer, you should consider this too.

Here are some of the ways you can confirm the reliability and reputation of the PCB manufacturer you want to use:

- Visit the manufacturer’s social media profiles to see how it has been using content marketing. This is important as it shows that the manufacturer isn’t too particular to make money, but is also looking at helping the customers.

- Visit the PCB manufacturer’s website to see the services offered. You may also check to see if there is an option to request a free quote.

- Check for the previous customers’ reviews. Try balancing their reviews and responses to the manufacturer’s services to see if they are good or bad.

- Take a survey to see the number of persons that will vote in favor of hiring the PCB manufacturer over the competing brands.

3. Turnaround Time

No matter how long you want the heavy copper PCB design to be delivered, you always wished it were early.

Therefore, focus your search for the best PCB manufacturer on the brand that can offer you faster delivery.

Besides, the design and pattern of the heavy copper PCB isn’t something that will take all the time in the world. Instead, the compact design ensures that all the necessary components and properties are assembled in a good time.

4. Availability of Tools

The PCB manufacturer you want to hire for your PCB manufacturing should have all the relevant tools and equipment required for making the project successful.

5. Replaceable Components

It is one thing to get in touch with the best heavy copper PCB factory or manufacturer. It is another thing to select the best manufacturer that can always provide the replacement parts of the PCB.

It is important to have this in mind because the PCB may develop some faults that will require the replacement of the parts. When you don’t have that on the ready, it may mean that the PCB wouldn’t be repaired.

6. Re-Installation and Repair Services

If the PCB factory can provide the replacement parts for the PCB, it should also fix the same.

You must consider and prioritize a PCB manufacturer that offers repair services for the Printed Circuit Boards (PCBs). The manufacturer should also offer re-installation services required for fixing the components after repairs.

7. Best Delivery Service

You should also check to see that the PCB manufacturer has the best delivery service. It is important to consider that because if the delivery service is excellent, it wouldn’t be long before the manufacturer will send the PCBs to you.

You also want to check the manufacturer’s website where you can see if the manufacturer has a dedicated delivery system. Also, check for the average delivery time that it will take the manufacturer to ship the PCBs to you once they are ready.

8. Certified Manufacturer

The other factor you must consider is the certification of the PCB manufacturer. It is pertinent to have this in mind because if the manufacturer doesn’t have the relevant certifications, it means that the quality of the PCB may be compromised.

One good reason why you should select a PCB manufacturer based on the certifications is because of the outcome of the job. Ideally, you are aiming to get the job done because of the manufacturer’s compliance with the laid-down rules and regulations in the industry.

9. Quality Check

While the experience and expertise of the PCB manufacturer count, the quality of the boards should count as well. It is important to check for the quality of the Printed Circuit Boards (PCBs) ahead of the design and manufacturing of the boards.

The best way to go about this is by checking through the manufacturing and testing procedures of the heavy copper PCB factory. That way, you will confirm the superiority and quality of the materials every time.

10. Be Specific About the Manufacturer You Want

There are many ways to calculate the features that make a PCB manufacturer the best out of its equals. Some of those are the type of PCB design services rendered and the entire procedures involved in the design.

First, you can select a printed circuit board manufacturing company based on the design only format. It means that the manufacturer will only design the heavy copper PCB and nothing more.

On the other hand, you may want to hire the services of a PCB manufacturer that can handle the entire process from start to finish. Some of the areas of consideration are the procurement of the PCB parts, the design, the assemblage, the fabrication, and the testing ahead of the delivery.

————————————————————-

Request Heavy Copper PCB Quote, Pls Send PCB File to Sales@raypcb.com Now

————————————————————-

Why Would My Heavy Copper PCB Fail?

As much as the heavy copper printed circuit board is effective, it may have some challenges.

You must understand this at all times so it wouldn’t come as a surprise when the board develops some faults.

Here are some of the problems that may cause the heavy copper PCB to have some faults along the line:

Age

The longer the heavy copper PCB is in use, the more the chances of developing faults increases.

Therefore, you must always have in mind that the age of the PCB tends to have some roles to play in the failure of the board now or in the future.

Burnt Components

The PCB manufacturer may have made the mistake of using some burnt components to manufacture the board.

If that is the case, the failure or malfunctioning of the heavy copper PCB may be prominent after a while.

Low-Quality Materials

Sometimes, you may be working on a budget and have some few funds to spare. So, you should endeavor to use high-quality materials for your extreme copper PCB designs.

Final Words

The thickness of the printed circuit board (PCB) helps you to manufacture the best and quality PCBs.

That is why you must endeavor to use the services of an excellent and experienced PCB manufacturer that will help give the copper layer of the PCB the desired thickness for long-lasting effects.

How do you select the best heavy copper PCB factory/manufacturer?

Comments are closed