Have you been looking for a way to get cheap PCB fab? You see, it is not always easy to find a PCB manufacturing company that offers this service for “cheap.” However, in this article, you will find out everything you need to know about PCB fabrication or “PCB Fab” for short.

What is PCB Fabrication?

It is the process of building the “raw circuit board” that doubles as the foundation of the Printed Circuit Board (PCB).

Most often, it is one of the first processes involved in designing PCBs. If you are working with a reliable PCB fabrication company, you can be sure of getting the raw board designed in a way that it fits the target applications.

The Processes of PCB Fabrication

The techniques involved in designing the PCB board at the earliest stage are many, but we have broken some of them down.

The Important Considerations Come First

Before getting on the job, the cheap PCB fab company would first consider some of the important criteria. These are the considerations that determine the extent of the circuit board’s usage.

The following are some of the considerations made at this point:

- Target Applications: what are the typical applications that the circuit board will be used once it is designed? The dexterity of the design is determined by the type of applications and the hitches that may come with the design process.

- Functional Attributes: the attributes or technical properties of the PCB are also considered. The consideration helps the designer to modify the circuit boards, as per the different functions of these attributes in the target applications.

The PCB Fabrication Materials

Several materials, including layers and vias are used when making PCB fabricates. The following is a breakdown of some of the commonly-used PCB fabrication materials:

Vias

The function of the vias is to make an electrical connection of the PCB layers. Depending on the circuit board design technology or process, the types of vias may vary.

Below are some of the common vias types and how they work:

- Buried Vias: this is the most-used type of vias. It is typically used when connecting the circuit board’s internal layers – especially during the fabrication process.

- Through-Hole Vias: as the name signifies, the through-hole vias is passed through a hole into the Printed Circuit Board (PCB). The through-hole vias works best with circuit board fabrications made with the Through-Hole Technology (THT).

- Blind Vias: this type of vias is “blind” in the sense that it doesn’t necessarily make the way through the circuit board.

The Base Materials

The common base material used with a PCB is the Glass-Reinforced Epoxy. Also known as the FR-4 material, it is used to enable low conductivity, and flame-resistance in the Printed Circuit Board (PCB).

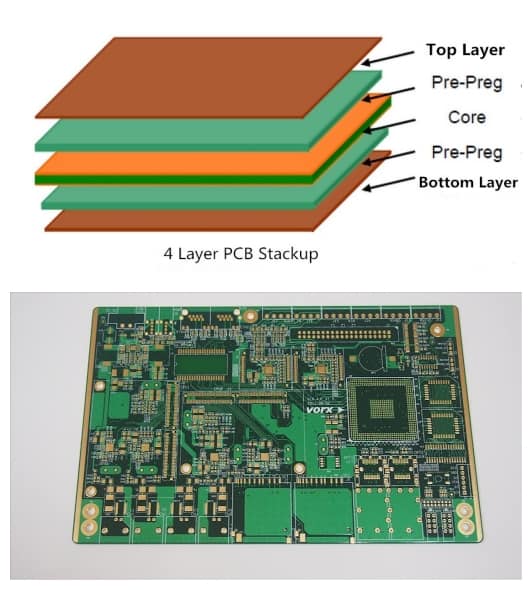

Layers

The PCB layers are the materials used for improving the efficiency and high-performance of the PCBs.

Depending on the type of Printed Circuit Board (PCB) design, the layers can either be one (single-sided) or several (multi-layered PCBs).

One thing you want to have in mind is that the layers are configurable or fabricated to fit into the respective uses.

Parameter Specifications

Since the PCB fabrication process involves the combination of the layers and the necessary patterns needed for the board design; it is imperative to be careful when working on it.

For that purpose, the consumer and the PCB fabrication vendor should put heads together to come up with the specifics, as per the consumer’s requirements.

The important specifications here include:

- Copper balancing

- The configuration and stackup for the Printed Circuit Board (PCB)

- The types of vias to use in the board.

- The minimum spacing and tracing width requirements.

Submission of the Final Schematics

The schematics include the considerations of the circuit board properties, as well as the final agreements on the circuit board’s design.

These are compiled into different data files and submitted to the PCB fabrication company. Examples of the data files submitted are:

- Netlist

- Bill of Materials (BOMs)

- Gerber files (these contain the respective board layer image files)

- Test point locations

- The Pick-and-Place (XY locations) in the circuit board.

List of the Best Cheap PCB Fabrication Companies

Now that you know some of the important processes that go into making a PCB fabrication, let us now look at some of the vendors.

1. Rayming PCB & Assembly

Also called RayPCB, it is a China-based PCB fabrication company. The company has been using latest technologies to manufacture different kinds of PCBs in the last 15 years.

One of the outstanding advantages of working with RayPCB is the extensive list of cheap PCB fabrication services it offers.

The following are some of the PCB fabrication services the company offers at the time of writing:

- Ceramic PCB

- Teflon PCB

- Multilayer PCB

- LED PCB

- Taconic PCB

- HDI PCB

- Rigid-Flex PCB

- Heavy Copper PCB

Lead time is one of the important considerations when choosing a PCB manufacturer. As a consumer, you want to work with a company that gets the job done in a few days or weeks – depending on the volume of work.

RayPCB has a combination of experts in PCB fabrication and the updated technological processes. This is the reason why the company has been able to cater to the needs of over 6,000 electronic contract customers and up to 10,000 electronic engineers.

You can be confident of getting maximum priority for your PCB fabrication project. Contact RayPCB today!

2. JHYPCB

The process of fabricating PCBs vary, depending on the board specifications, and of course, the type of circuit board. JHYPCB is your reliable cheap PCB fab if you are looking to get the job done in the shortest time possible.

The company describes itself as a reliable PCB manufacturer that “offers rapid PCB prototype service for quick-turn fabrication at high-quality and low cost.”

The most important point to note here is that the company is that JHYPCB specializes in the production of PCB fabrications that are used for prototyping.

From the list of services that it offers in that regard, we can see that it offers just the:

- Quick-Turn Prototype PCB Fabrication and;

- Low-Cost PCB Prototype Fabrication

Turnaround Time

Since it specializes in the quick-turn and low-cost PCB prototypes, one can expect that JHYPCB lives up to that promise.

Indeed, the company lives up to expectations, as it offers a fast turnaround time. You can expect your double-sided PCB prototype fabrication to be ready in 8 hours. However, if you are ordering for more prototypes, you can expect a higher lead time.

For example, the small batches can take up to 24 hours, expect a lead time of 36 hours for the multilayer PCB prototype and up to 3 working days for both the small and medium quantities.

3. Avanti Circuits

Avanti Circuits is an American PCB company that offers a wide range of fabrication services. It specializes in PCB fabrication and assembly – a combination of two important PCB designing services.

Target Applications

The range of PCB services offered by this company extend to different sectors. The following are some of the popular industries that the company manufactures PCB fabrications for:

- Military

- Medical

- Automotive

- Aerospace

Quick-Turn Services

Avanti Circuits also provides a wide range of fast-paced PCB services, one of which is the quick-turn PCBs. The company understands that the customers need the circuit boards to be ready in good time.

It offers the quick-turn PCB service to both PCB hobbyists and engineers from around the world. That way, these consumers get high-quality PCBs needed to start their projects in real-time.

4. PCBWay

One of the common uses of PCB fabrications is to get an idea of what the final design will be and how it would impact the real-world use cases. For that reason, PCBWay has opted to specialize in the fabrication of circuit boards used for research work purposes.

The company fabricates these circuit boards in smaller volumes and the lead time can be anywhere between a few hours and a few days. For example, the vendor promises to get up to 1m2 of standard PCBs fabricated in 24 hours. The lead time for the 5m2 and 10m2 standard PCBs are 4 days and 5 days, maximum.

However, if you are working with the advanced PCBs, the lead time may be a bit higher. The build/lead time of 5m2 two-layered PCBs is 7 days, while that of the 5m2 6 and 8-layered PCBs is 9 days.

Reduced Costs

One of the major advantages of working on PCB fabrications is the affordability. You can expect much more cost reductions when working with PCBWay. The company is able to offer the best PCB fabrication services at the lowest costs because of the following factors:

- The company replaces the conductive adhesive technology with the chemical process for pads.

- PCBWay also offers a reduced cost in the shipping costs. Customers can expect to pay less for the fabricated circuit boards, weighing less than a Kilogram (KG).

5. Electronic Integration Inc.

This is one of the leading fabricators of Printed Circuit Boards (PCBs). With over 25 years of experience in the PCB market, Electronic Integration Inc. passes as one of the best companies to contract for your PCB needs.

In terms of PCB fabrication, the company expects, among many other things, that the customers should provide the Gerber files for the silkscreen layer, copper layer and soldermask layer.

Customers are also required to provide the total quantities of PCBs required, the Excellon Format NC Drill File and the Gerber file containing the detailed drawings of the hole locations, slots and cutouts.

6. Best Technology

Best Technology, also known as Best PCB, specializes in the provision of full turnkey manufacturing solutions for the Printed Circuit Boards (PCBs). The company also offers PCB fabrication, assembly and prototyping solutions.

The company takes the process seriously, which is why it partners with the consumers throughout the design iterations, offering updates and requesting relevant information to ensure that the design comes out nice.

The company promises to offer the best PCB design, based on the schematic or design files you generated. But if you have an existing PCB design needing further optimization or updating, rest assured that Best Technology will handle that perfectly for you.

The Difference between PCB Fabrication and PCB Assembly

Most times, people are confused about the processes involved in making Printed Circuit Boards (PCBs). These processes range from the designs to the final production of the standard PCBs.

The commonly-compared processes are the PCB Fabrication and the PCB Assembly. What do they mean and what are the core differences?

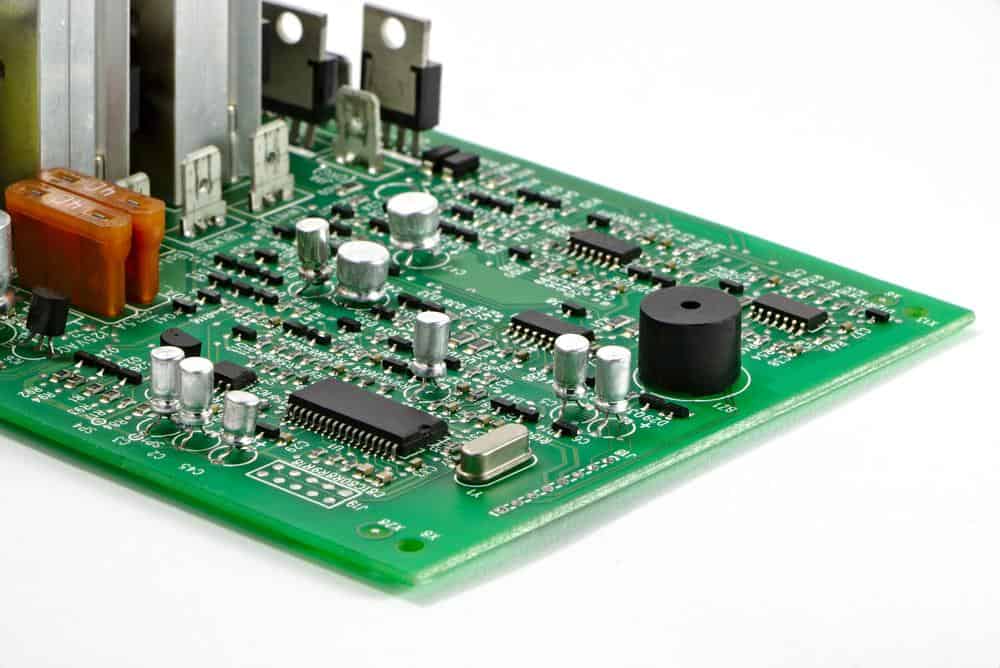

PCB Fabrication has to do with the initial design of a circuit board. In this case, the concentration is on getting the first design that would later be subjected to a series of procedures before the final board production. The process also includes the manufacturing of the circuit board, without placing any components on it.

On the other hand, PCB Assembly has to do with the last stages of designing a Printed Circuit Board (PCB). Here, the PCB designer places or mounts the electrical components on the board.

Therefore, the differences between the PCB Fabrication and the PCB Assembly processes are viz:

- PCB Fabrication involves the initial designs and manufacturing of the circuit board, while the PCB Assembly takes place after the designs are complete.

- PCB Fab involves the design of the board for prototypes to be made, while the PCB Assembly is usually the final design of the board.

Important Considerations for Cheap PCB Fabrication

The fact that making fabricates of PCBs is feasible today doesn’t mean that you should ignore some vital elements.

Below are some of the additional considerations, which when put into the respective perspectives, help to improve the circuit board fabrication process:

Average Volume

The cheap PCB fab company should offer a feasible lead time. Depending on the number of circuit boards to be fabricated, the lead time can be between 24 hours and 8 days.

Design Process

Will the cheap PCB fabrication company offer the designs alone or would it outsource the same? RayPCB handles all the PCB fabrication solutions in-house, and that is one of the reasons why are services are affordable.

Concluding Thoughts

The choice of a company that specializes in cheap PCB fabrication always borders on the volume of circuit boards it can handle, the design iterations and the years of experience.

If you are looking for the best PCB fabrication company with an emphasis on quality and low-cost designs, look no further than RayPCB. Contact us today for a quotation.

Comments are closed